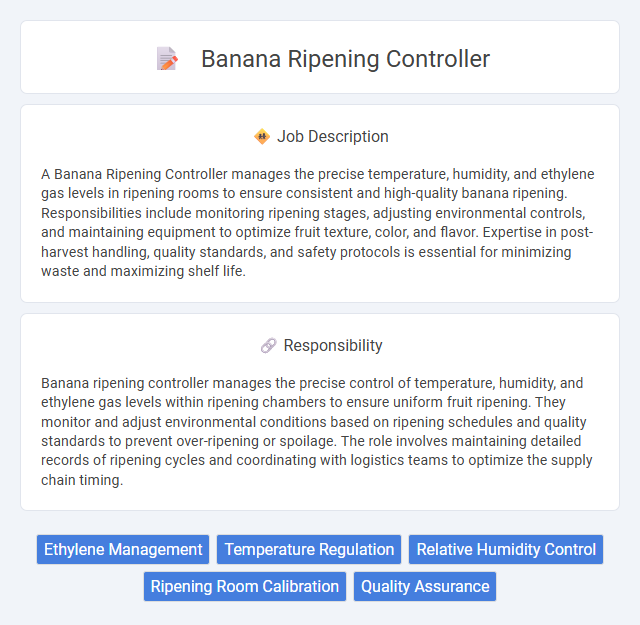

A Banana Ripening Controller manages the precise temperature, humidity, and ethylene gas levels in ripening rooms to ensure consistent and high-quality banana ripening. Responsibilities include monitoring ripening stages, adjusting environmental controls, and maintaining equipment to optimize fruit texture, color, and flavor. Expertise in post-harvest handling, quality standards, and safety protocols is essential for minimizing waste and maximizing shelf life.

Individuals with strong attention to detail and an interest in agricultural processes might be suitable for a banana ripening controller position. Those comfortable working in controlled environments and handling temperature and humidity monitoring could likely thrive in this role. People who prefer repetitive tasks or physical activity might find this job more aligned with their strengths.

Qualification

A Banana Ripening Controller must possess a strong background in post-harvest technology, horticulture, or food science with practical experience in controlled atmosphere storage and ethylene regulation. Proficiency in using ripening chambers, monitoring temperature, humidity, and gas composition ensures optimal fruit quality and shelf life. Familiarity with quality control standards, safety protocols, and data logging software is essential to maintain consistency and meet industry regulations.

Responsibility

Banana ripening controller manages the precise control of temperature, humidity, and ethylene gas levels within ripening chambers to ensure uniform fruit ripening. They monitor and adjust environmental conditions based on ripening schedules and quality standards to prevent over-ripening or spoilage. The role involves maintaining detailed records of ripening cycles and coordinating with logistics teams to optimize the supply chain timing.

Benefit

A banana ripening controller likely improves the precision of the ripening process, leading to more consistent fruit quality and reduced waste. This role may contribute to optimizing storage conditions, which can extend shelf life and enhance customer satisfaction. It is probable that such control also supports operational efficiency, potentially lowering costs and increasing overall profitability for producers or retailers.

Challenge

Banana ripening controller jobs likely involve managing the delicate balance of temperature, humidity, and ethylene gas to ensure optimal fruit quality and shelf life. Challenges may include anticipating fluctuations in storage conditions and adjusting controls to prevent premature over-ripening or spoilage. Precise monitoring and quick decision-making are probably essential to maintain consistent ripening outcomes and meet supply chain demands.

Career Advancement

A Banana Ripening Controller plays a critical role in managing the optimal conditions for fruit maturation, ensuring quality standards and reducing waste. Expertise in temperature regulation, ethylene gas control, and post-harvest technology forms a foundation for advancing to senior roles such as Production Manager or Supply Chain Supervisor. Continuous skill development in data analytics and quality assurance within this niche enhances opportunities for leadership positions in the agricultural and food distribution industries.

Key Terms

Ethylene Management

Banana ripening controllers specialize in regulating ethylene gas to optimize fruit maturation and shelf life. Precise ethylene management accelerates or delays ripening by controlling concentration levels, temperature, and humidity within ripening chambers. Advanced monitoring systems ensure uniform ripening, reduce spoilage, and maximize market readiness.

Temperature Regulation

Temperature regulation is crucial in banana ripening controllers to ensure uniform and optimal ripening by maintaining conditions typically between 14degC and 18degC. Precise control of temperature prevents premature ripening or chilling injury, enhancing shelf life and quality. Advanced sensors and automated systems adjust temperature settings dynamically, responding to real-time data for efficient ripening processes.

Relative Humidity Control

Banana ripening controllers regulate the relative humidity within ripening chambers to maintain an ideal environment of 90-95% RH, preventing moisture loss and ensuring uniform ripening. Precise humidity control minimizes shrinkage and weight loss while reducing the risk of fungal growth and spoilage during the ripening process. Advanced sensors and automated systems continuously monitor and adjust humidity levels, optimizing banana quality and shelf life for commercial distribution.

Ripening Room Calibration

Banana ripening controller jobs involve precise management of ripening rooms, ensuring optimal temperature, humidity, and ethylene gas levels to achieve uniform fruit maturity. Ripening room calibration requires regular sensor verification and adjustment of control systems to maintain consistent environmental conditions that meet industry standards. Accurate calibration enhances product quality, minimizes waste, and supports compliance with food safety regulations.

Quality Assurance

A Banana Ripening Controller ensures optimal fruit quality by monitoring temperature, humidity, and ethylene gas levels throughout the ripening process. This role involves strict adherence to quality assurance protocols to prevent spoilage and achieve consistent ripeness standards. Advanced data tracking and environmental controls are essential for maintaining the supply chain's integrity from warehouse to retail.

kuljobs.com

kuljobs.com