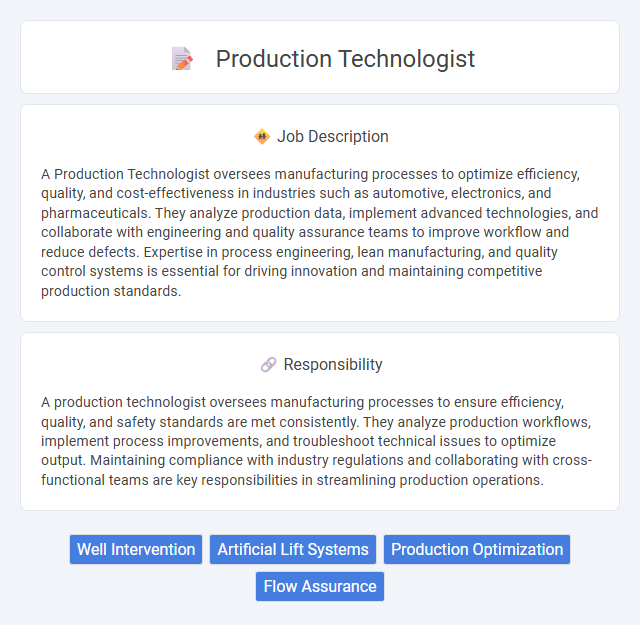

A Production Technologist oversees manufacturing processes to optimize efficiency, quality, and cost-effectiveness in industries such as automotive, electronics, and pharmaceuticals. They analyze production data, implement advanced technologies, and collaborate with engineering and quality assurance teams to improve workflow and reduce defects. Expertise in process engineering, lean manufacturing, and quality control systems is essential for driving innovation and maintaining competitive production standards.

Individuals who possess strong analytical skills and an interest in manufacturing processes will likely find the role of a production technologist suitable. Those comfortable working in fast-paced, detail-oriented environments with a focus on continuous improvement may thrive in this position. People who prefer routine tasks without much variation might not find this job as fitting due to its dynamic and problem-solving nature.

Qualification

A Production Technologist typically requires a bachelor's degree in industrial engineering, manufacturing technology, or a related field, accompanied by expertise in process optimization and quality control. Proficiency in CAD software, knowledge of manufacturing systems, and hands-on experience with production machinery are essential qualifications. Strong analytical skills coupled with an understanding of Lean Manufacturing and Six Sigma methodologies are highly valued for this role.

Responsibility

A production technologist oversees manufacturing processes to ensure efficiency, quality, and safety standards are met consistently. They analyze production workflows, implement process improvements, and troubleshoot technical issues to optimize output. Maintaining compliance with industry regulations and collaborating with cross-functional teams are key responsibilities in streamlining production operations.

Benefit

A production technologist likely improves manufacturing efficiency by identifying and implementing optimized processes, which can lead to cost reductions and higher product quality. The role may also provide opportunities for career growth due to its technical nature and involvement in innovative production techniques. Employees in this field probably experience a sense of achievement from enhancing operational workflows and contributing to successful product launches.

Challenge

A Production Technologist likely faces challenges in optimizing manufacturing processes to boost efficiency while maintaining product quality. They may encounter difficulties in troubleshooting equipment malfunctions and implementing new technologies under tight deadlines. Adapting to changing production demands and ensuring compliance with safety standards could present ongoing hurdles in this role.

Career Advancement

Production technologists play a crucial role in optimizing manufacturing processes, improving product quality, and ensuring efficient resource utilization. Career advancement opportunities often lead to senior roles such as Production Manager, Process Engineer, or Operations Director, where strategic decision-making and leadership skills are essential. Gaining expertise in automation technologies, Lean Manufacturing, and Six Sigma methodologies significantly enhances prospects for promotion and higher salaries.

Key Terms

Well Intervention

A Production Technologist specializing in Well Intervention optimizes oil and gas well performance through advanced techniques such as coiled tubing, wireline operations, and hydraulic fracturing. Expertise in evaluating well integrity, diagnosing production issues, and implementing remedial actions ensures maximum reservoir productivity and reduced downtime. Proficiency in real-time monitoring systems and reservoir management software enhances decision-making for efficient well intervention strategies.

Artificial Lift Systems

Production technologists specializing in Artificial Lift Systems optimize oil and gas extraction by designing, implementing, and maintaining lift methods such as rod pumps, gas lift, and electric submersible pumps. They analyze reservoir characteristics and well performance data to select the most efficient artificial lift techniques that enhance fluid flow and maximize hydrocarbon recovery. Their role involves continuous monitoring and troubleshooting of lift systems to ensure operational efficiency and extend well productivity.

Production Optimization

A Production Technologist specializes in enhancing manufacturing processes to maximize efficiency, product quality, and cost-effectiveness. They analyze production data, implement advanced technologies, and optimize workflow to reduce downtime and minimize waste. Expertise in process engineering and continuous improvement methodologies drives sustainable production optimization in various industries.

Flow Assurance

A Production Technologist specializing in Flow Assurance ensures continuous, efficient transportation of hydrocarbons through pipelines by preventing blockages caused by hydrate formation, wax deposition, or corrosion. Expertise in thermal modeling, chemical treatments, and real-time monitoring systems is essential to maintain optimal flow conditions under varying pressure and temperature environments. Collaboration with drilling and reservoir engineers supports integrated solutions to maximize production rates and minimize downtime.

kuljobs.com

kuljobs.com