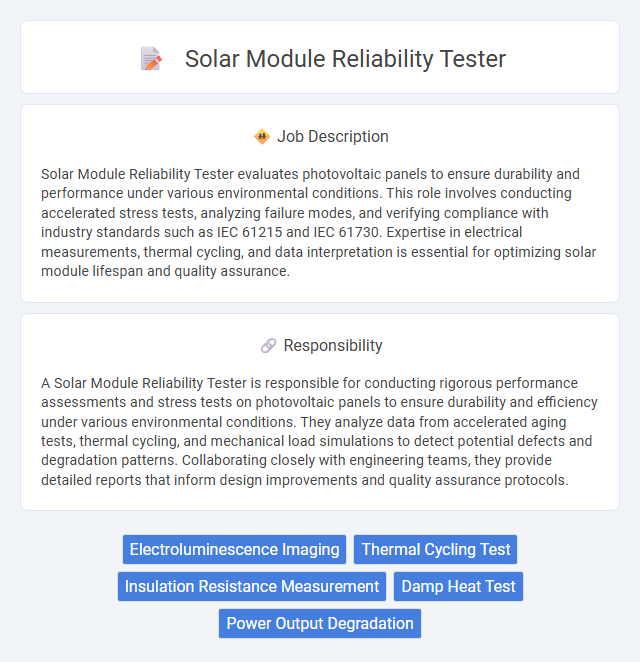

Solar Module Reliability Tester evaluates photovoltaic panels to ensure durability and performance under various environmental conditions. This role involves conducting accelerated stress tests, analyzing failure modes, and verifying compliance with industry standards such as IEC 61215 and IEC 61730. Expertise in electrical measurements, thermal cycling, and data interpretation is essential for optimizing solar module lifespan and quality assurance.

Candidates with strong analytical skills and attention to detail are likely to perform well as Solar Module Reliability Testers. Individuals who are comfortable working with technical equipment and interpreting test data may find this role suitable. Those who prefer hands-on, precise tasks and have a background in electronics or renewable energy might be better aligned with the job's demands.

Qualification

A Solar Module Reliability Tester must possess a strong background in electrical engineering or renewable energy technology, with hands-on experience in photovoltaic (PV) systems testing. Proficiency in using specialized equipment such as electroluminescence imaging, thermal cycling chambers, and IV tracer testers is essential for accurate reliability assessments. Familiarity with industry standards like IEC 61215 and IEC 61730 ensures compliance and enhances testing precision in assessing solar module durability and performance.

Responsibility

A Solar Module Reliability Tester is responsible for conducting rigorous performance assessments and stress tests on photovoltaic panels to ensure durability and efficiency under various environmental conditions. They analyze data from accelerated aging tests, thermal cycling, and mechanical load simulations to detect potential defects and degradation patterns. Collaborating closely with engineering teams, they provide detailed reports that inform design improvements and quality assurance protocols.

Benefit

A Solar Module Reliability Tester likely enhances the quality and durability of solar panels by identifying potential defects early in the manufacturing process, potentially reducing product failures and warranty claims. This role probably supports innovation by providing crucial data that informs design improvements and material selections. Engaging in this position may offer the chance to contribute to sustainable energy solutions while gaining expertise in advanced testing technologies.

Challenge

Working as a Solar Module Reliability Tester likely involves navigating complex technical challenges to accurately assess the durability and performance of solar modules under various environmental conditions. There is a probability of encountering difficulties related to precise data analysis and interpreting long-term stress test results, which demand advanced problem-solving skills. The role probably requires continuous adaptation to evolving testing standards and the integration of innovative technologies to ensure the reliability of solar products.

Career Advancement

A Solar Module Reliability Tester plays a critical role in ensuring the durability and performance of photovoltaic panels through rigorous testing and data analysis. Expertise in this field opens pathways to advanced positions such as Quality Assurance Manager, Research and Development Lead, or Technical Specialist within the renewable energy sector. Continuous skill enhancement in testing methodologies, failure analysis, and emerging solar technologies significantly accelerates career growth and industry recognition.

Key Terms

Electroluminescence Imaging

The Solar Module Reliability Tester specializes in using Electroluminescence Imaging (ELI) to detect micro-cracks, broken cells, and other defects in photovoltaic panels that impact performance and durability. This advanced non-destructive testing method captures high-resolution images by passing current through solar cells and measuring emitted infrared light, enabling early identification of potential failure points. Expertise in interpreting ELI results is crucial for ensuring optimal quality control and extending the operational lifespan of solar modules.

Thermal Cycling Test

The Solar Module Reliability Tester specializes in conducting Thermal Cycling Tests to evaluate photovoltaic module durability against temperature fluctuations. This test simulates extreme hot and cold cycles, ensuring solar panels can withstand real-world environmental stress without performance degradation. Expertise in monitoring key parameters like insulation resistance and power output during these tests guarantees compliance with industry standards such as IEC 61215 and IEC 61730.

Insulation Resistance Measurement

Solar module reliability testers perform critical insulation resistance measurement to ensure photovoltaic panels maintain electrical integrity under operational stress. Accurate insulation resistance testing identifies potential leakage currents and insulation degradation, directly impacting solar module efficiency and safety. This process involves applying high voltage to the module and measuring resistance levels to detect defects that could cause performance loss or electrical hazards over time.

Damp Heat Test

The Solar Module Reliability Tester conducts Damp Heat Tests to evaluate solar panel resilience under high humidity and temperature conditions, typically at 85degC and 85% relative humidity for 1000 hours. This test ensures module durability by detecting potential corrosion, delamination, and electrical degradation, critical for long-term performance in diverse climates. Accurate data collection and analysis from these tests support quality assurance and compliance with international standards like IEC 61215.

Power Output Degradation

A Solar Module Reliability Tester specializes in evaluating the power output degradation of photovoltaic panels over time, ensuring long-term performance and durability. This role involves simulating environmental stress factors such as temperature fluctuations, humidity, and UV exposure to identify decreases in energy efficiency. Accurate measurement and analysis of power degradation rates help optimize manufacturing processes and improve solar module warranties.

kuljobs.com

kuljobs.com