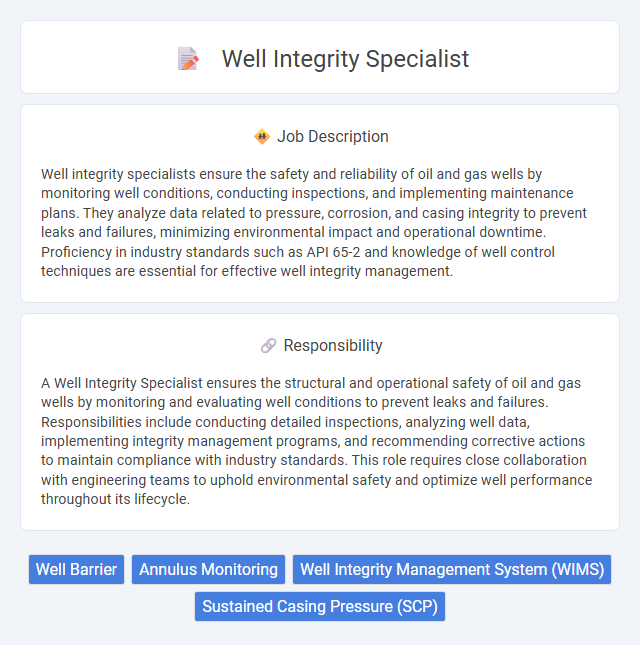

Well integrity specialists ensure the safety and reliability of oil and gas wells by monitoring well conditions, conducting inspections, and implementing maintenance plans. They analyze data related to pressure, corrosion, and casing integrity to prevent leaks and failures, minimizing environmental impact and operational downtime. Proficiency in industry standards such as API 65-2 and knowledge of well control techniques are essential for effective well integrity management.

Individuals with strong analytical skills and a keen attention to detail are likely to excel as well integrity specialists. This role probably suits those who thrive in high-pressure environments and possess a solid understanding of engineering principles and safety regulations. Candidates who may struggle with repetitive assessments or stringent compliance protocols might find this job challenging.

Qualification

A Well Integrity Specialist must possess a degree in petroleum engineering or related fields, coupled with extensive experience in well design, drilling, and completion. Proficiency in industry standards such as API, ISO, and NORSOK is essential to ensure compliance with safety and environmental regulations. Strong analytical skills and expertise in well integrity management systems, monitoring technologies, and risk assessment techniques are critical for maintaining well safety and preventing failures.

Responsibility

A Well Integrity Specialist ensures the structural and operational safety of oil and gas wells by monitoring and evaluating well conditions to prevent leaks and failures. Responsibilities include conducting detailed inspections, analyzing well data, implementing integrity management programs, and recommending corrective actions to maintain compliance with industry standards. This role requires close collaboration with engineering teams to uphold environmental safety and optimize well performance throughout its lifecycle.

Benefit

A Well Integrity Specialist likely enhances operational safety by preventing well failures, which may reduce costly downtime and environmental hazards. Their expertise probably contributes to extending well lifespan, improving overall asset value and efficiency. Companies hiring for this role can expect improved regulatory compliance, potentially avoiding penalties and fostering sustainable production practices.

Challenge

The role of a well integrity specialist likely involves addressing complex challenges related to maintaining the structural and operational safety of wells. These challenges might include predicting potential failures and developing effective prevention strategies under varying geological conditions. Handling unexpected anomalies in well behavior could require advanced problem-solving skills and constant adaptation to new technologies.

Career Advancement

A Well Integrity Specialist plays a crucial role in ensuring the safety and efficiency of oil and gas wells by monitoring and maintaining well integrity throughout the lifecycle. Career advancement opportunities include moving into senior specialist roles, project management, or leadership positions within engineering and safety teams. Gaining certifications such as API Well Integrity and expanding skills in risk assessment and regulatory compliance can significantly enhance promotion prospects.

Key Terms

Well Barrier

A Well Integrity Specialist ensures the safety and reliability of well barriers by designing, monitoring, and maintaining pressure control systems throughout the well lifecycle. Expertise in evaluating casing, cementing quality, and blowout preventer functionality is essential for preventing leaks and environmental hazards. Mastery of industry standards such as API 65-2 and ISO 16530 improves risk management and compliance in well integrity assessments.

Annulus Monitoring

A Well Integrity Specialist ensures safe and efficient hydrocarbon extraction by continuously monitoring annulus pressure and fluid levels to detect early signs of casing or tubing leaks. Expertise in advanced diagnostic tools like pressure transducers and acoustic sensors enables accurate assessment of annulus conditions, preventing well control incidents and environmental hazards. Proficiency in regulatory compliance and well integrity management systems supports the maintenance of structural stability and prolongs well lifespan.

Well Integrity Management System (WIMS)

A Well Integrity Specialist ensures the structural and operational safety of oil and gas wells by implementing and maintaining the Well Integrity Management System (WIMS). This role involves continuous monitoring, risk assessment, and compliance with industry standards to prevent well failure and environmental hazards. Expertise in pressure testing, cement evaluation, and corrosion control is essential for optimizing well longevity and safety.

Sustained Casing Pressure (SCP)

A Well Integrity Specialist specializing in Sustained Casing Pressure (SCP) is responsible for diagnosing, monitoring, and mitigating SCP issues to prevent wellbore leaks and ensure operational safety. This role involves analyzing pressure data, performing root cause assessments, and designing remediation programs to maintain casing integrity throughout the well's lifecycle. Expertise in well completion techniques, pressure testing, and regulatory compliance is critical to effectively manage SCP risks and optimize well performance.

kuljobs.com

kuljobs.com