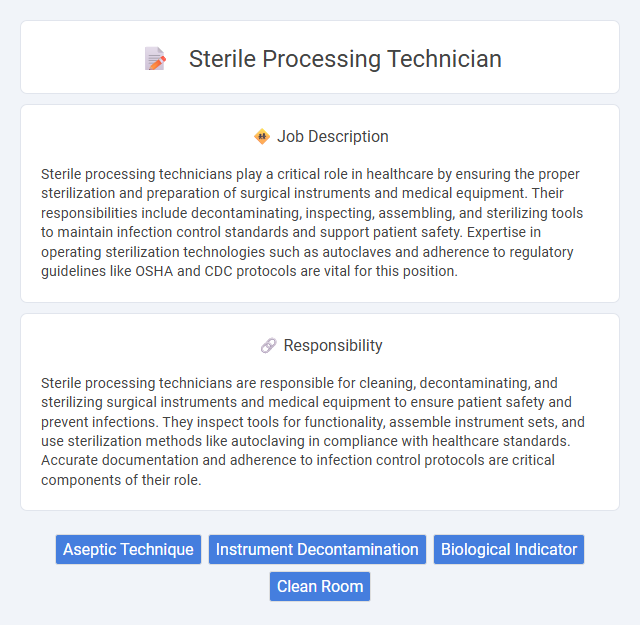

Sterile processing technicians play a critical role in healthcare by ensuring the proper sterilization and preparation of surgical instruments and medical equipment. Their responsibilities include decontaminating, inspecting, assembling, and sterilizing tools to maintain infection control standards and support patient safety. Expertise in operating sterilization technologies such as autoclaves and adherence to regulatory guidelines like OSHA and CDC protocols are vital for this position.

Individuals with strong attention to detail and a preference for organized, repetitive tasks are likely to thrive as sterile processing technicians. Those who may struggle with high-pressure environments or meticulous protocols might find this role challenging. The job seems suitable for people who value precision and consistency in maintaining medical equipment cleanliness.

Qualification

A Sterile Processing Technician must possess a high school diploma or equivalent and complete specialized training in sterile processing, often through accredited programs or on-the-job certification. Certification from organizations such as the Certification Board for Sterile Processing and Distribution (CBSPD) or the International Association of Healthcare Central Service Materiel Management (IAHCSMM) is highly preferred. Key qualifications include knowledge of infection control standards, proficiency in operating sterilization equipment, and adherence to healthcare safety protocols.

Responsibility

Sterile processing technicians are responsible for cleaning, decontaminating, and sterilizing surgical instruments and medical equipment to ensure patient safety and prevent infections. They inspect tools for functionality, assemble instrument sets, and use sterilization methods like autoclaving in compliance with healthcare standards. Accurate documentation and adherence to infection control protocols are critical components of their role.

Benefit

Sterile processing technicians likely enjoy benefits such as competitive salaries, comprehensive health insurance, and opportunities for career advancement. Access to ongoing training and certification programs increases job security and professional growth. Employee schedules often offer stability and work-life balance, contributing to overall job satisfaction.

Challenge

The role of a sterile processing technician likely involves managing the high challenge of maintaining strict infection control standards while ensuring surgical instruments are correctly sterilized and ready on time. There is a probable need to stay vigilant and detail-oriented in a fast-paced environment where any oversight could compromise patient safety. This position often demands continuous learning and adaptability to new sterilization technologies and protocols.

Career Advancement

Sterile processing technician roles offer clear career advancement paths through specialized certifications such as Certified Registered Central Service Technician (CRCST) and Certified Instrument Specialist (CIS). Gaining expertise in advanced sterilization techniques and quality control can lead to supervisory or management positions within healthcare facilities. Continuous professional development and hands-on experience enhance job prospects and salary growth in this field.

Key Terms

Aseptic Technique

Sterile processing technicians play a critical role in healthcare by ensuring surgical instruments are meticulously cleaned, sterilized, and prepared using aseptic techniques to prevent contamination and infection. Mastery of aseptic technique involves strict adherence to protocols such as proper hand hygiene, sterilization cycles, and maintaining sterile fields to uphold patient safety. Proficiency in these procedures directly impacts infection control outcomes in operating rooms and other clinical settings.

Instrument Decontamination

Sterile processing technicians specialize in instrument decontamination to eliminate microbial contaminants and prevent healthcare-associated infections. They use advanced sterilization techniques such as ultrasonic cleaning, thermal disinfection, and chemical immersion to ensure surgical instruments meet stringent safety standards. Precision in decontamination protocols directly impacts the efficacy of surgical procedures and patient outcomes.

Biological Indicator

Biological Indicators (BIs) play a critical role in a Sterile Processing Technician's responsibilities by validating the effectiveness of sterilization processes in healthcare facilities. These indicators contain resistant bacterial spores that provide a reliable measure of sterilizer performance when exposed, ensuring patient safety by confirming that instruments are free from microbial contamination. Proper handling, placement, and timely interpretation of BI results are essential skills that Sterile Processing Technicians must master to maintain compliance with infection control standards.

Clean Room

Sterile processing technicians ensure the meticulous cleaning, sterilization, and assembly of surgical instruments within controlled clean room environments to maintain strict infection control standards. They utilize advanced sterilization equipment and follow precise protocols to remove contaminants and prevent microbial growth, which is critical for patient safety. Expertise in clean room procedures and adherence to regulatory guidelines like those from the CDC and AAMI are essential to maintain the integrity of sterile supplies in healthcare facilities.

kuljobs.com

kuljobs.com