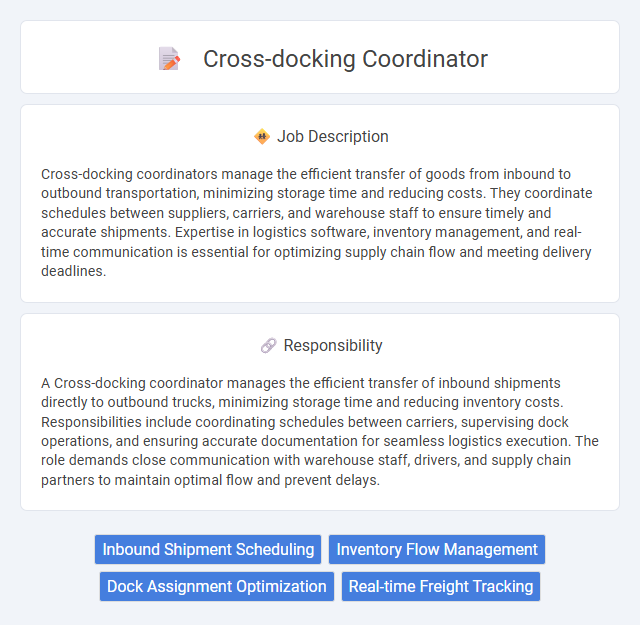

Cross-docking coordinators manage the efficient transfer of goods from inbound to outbound transportation, minimizing storage time and reducing costs. They coordinate schedules between suppliers, carriers, and warehouse staff to ensure timely and accurate shipments. Expertise in logistics software, inventory management, and real-time communication is essential for optimizing supply chain flow and meeting delivery deadlines.

Individuals with strong organizational skills and the ability to manage fast-paced environments are likely well-suited for a cross-docking coordinator role. Those who thrive under pressure, maintain attention to detail, and communicate effectively with multiple teams may find this position fitting. Conversely, people who prefer predictable routines and minimal multitasking might face challenges adapting to the dynamic nature of cross-docking operations.

Qualification

A Cross-docking Coordinator requires strong organizational skills and experience in warehouse management systems such as WMS and ERP software. Proficiency in inventory control, logistics coordination, and real-time shipping and receiving processes is essential to ensure efficient transfer of goods between inbound and outbound transportation. Candidates typically need a high school diploma or equivalent, with preference for certifications in supply chain management or logistics.

Responsibility

A Cross-docking coordinator manages the efficient transfer of inbound shipments directly to outbound trucks, minimizing storage time and reducing inventory costs. Responsibilities include coordinating schedules between carriers, supervising dock operations, and ensuring accurate documentation for seamless logistics execution. The role demands close communication with warehouse staff, drivers, and supply chain partners to maintain optimal flow and prevent delays.

Benefit

A Cross-docking coordinator likely improves warehouse efficiency by minimizing storage time and accelerating the distribution process. This role probably reduces handling costs and enhances inventory turnover, leading to potential savings for the company. Effective coordination may also increase customer satisfaction through faster delivery times and streamlined logistics.

Challenge

The role of a Cross-docking Coordinator likely involves managing tight schedules and coordinating multiple shipments to minimize delays and reduce storage costs. Challenges probably arise from balancing incoming and outgoing freight efficiently while adapting to unexpected disruptions such as late arrivals or inventory discrepancies. Strong organizational skills and the ability to quickly problem-solve may be essential to maintaining smooth operations in a fast-paced environment.

Career Advancement

Cross-docking coordinators play a crucial role in streamlining supply chain operations by managing the efficient transfer of goods without long-term storage. Mastery in logistics software and inventory management enhances opportunities for promotion to logistics manager or supply chain analyst roles. Developing expertise in real-time data analysis and vendor communication significantly accelerates career advancement within warehousing and distribution sectors.

Key Terms

Inbound Shipment Scheduling

A Cross-docking Coordinator specializing in Inbound Shipment Scheduling ensures timely arrival and efficient unloading of goods by coordinating with carriers and warehouse teams. They utilize real-time tracking systems and scheduling software to optimize dock assignments and minimize wait times. Accurate inbound scheduling directly reduces storage costs and accelerates the flow of products through the supply chain.

Inventory Flow Management

Cross-docking coordinators play a critical role in inventory flow management by ensuring the seamless transfer of goods from inbound to outbound transportation without prolonged storage. They optimize the coordination of shipments, reduce warehouse handling time, and improve overall supply chain efficiency. Accurate scheduling and real-time tracking enable effective inventory turnover, minimizing stockouts and excess inventory.

Dock Assignment Optimization

Cross-docking coordinators specialize in optimizing dock assignments to streamline loading and unloading processes, reducing wait times and increasing throughput. They analyze shipment schedules, vehicle types, and cargo volume to allocate dock space efficiently, minimizing bottlenecks and labor costs. Leveraging real-time data and advanced software, coordinators ensure seamless flow of goods, enhancing overall supply chain performance.

Real-time Freight Tracking

A Cross-docking coordinator manages the seamless transfer of goods between incoming and outgoing shipments to minimize storage time and optimize supply chain efficiency. Real-time freight tracking systems provide critical data on shipment location, status, and estimated arrival times, enabling the coordinator to promptly adjust workflows and prevent delays. Leveraging GPS and RFID technologies, the coordinator ensures accurate inventory management and timely coordination between freight carriers and warehouse operations.

kuljobs.com

kuljobs.com