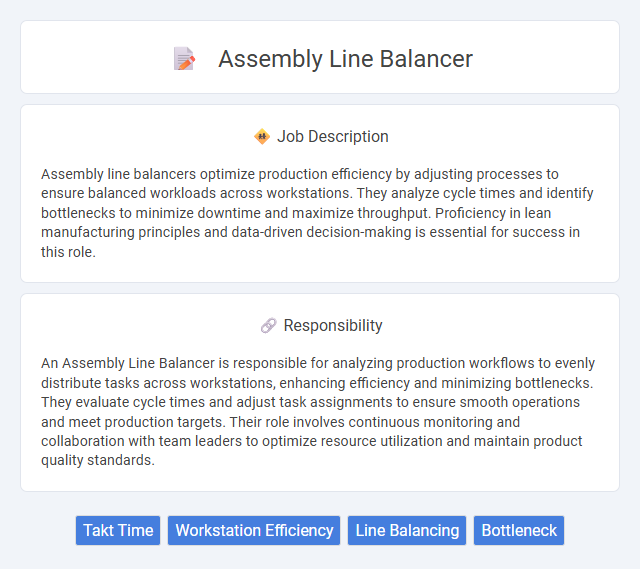

Assembly line balancers optimize production efficiency by adjusting processes to ensure balanced workloads across workstations. They analyze cycle times and identify bottlenecks to minimize downtime and maximize throughput. Proficiency in lean manufacturing principles and data-driven decision-making is essential for success in this role.

Individuals with strong attention to detail and the ability to work methodically may be well-suited for the role of an assembly line balancer, as the job often requires analyzing workflow efficiency and making precise adjustments. Those who can handle repetitive tasks without loss of concentration and possess good problem-solving skills are probably more likely to succeed in this position. However, people who struggle with monotony or have difficulty maintaining focus under strict production schedules might find this job less suitable.

Qualification

An Assembly Line Balancer must possess strong analytical skills and experience with industrial engineering principles to optimize workflow and improve efficiency. Proficiency in data analysis tools such as Excel or specialized software is essential for balancing workstations and minimizing production bottlenecks. A background in manufacturing, mechanical engineering, or operations management, along with attention to detail and problem-solving abilities, is critical for success in this role.

Responsibility

An Assembly Line Balancer is responsible for analyzing production workflows to evenly distribute tasks across workstations, enhancing efficiency and minimizing bottlenecks. They evaluate cycle times and adjust task assignments to ensure smooth operations and meet production targets. Their role involves continuous monitoring and collaboration with team leaders to optimize resource utilization and maintain product quality standards.

Benefit

Assembly line balancer jobs likely improve production efficiency by ensuring tasks are evenly distributed, which may reduce bottlenecks and downtime. Employees might experience less physical strain and fatigue due to balanced workloads, potentially enhancing job satisfaction. Companies could see increased output quality and consistency as a probable result of optimized assembly line processes.

Challenge

Assembly line balancer jobs likely present challenges in managing workflow efficiency while minimizing bottlenecks. Balancing tasks demands careful analysis and adjustment to meet production targets, which may require problem-solving under time constraints. Effective collaboration with team members is probable to ensure smooth operations and maintain consistent output quality.

Career Advancement

Assembly line balancers optimize workflow by evenly distributing tasks to enhance production efficiency and reduce bottlenecks. Mastery in process analysis, time study methods, and lean manufacturing principles can lead to roles such as production supervisor or industrial engineer. Continuous skill development in automation technology and team management increases opportunities for career growth within manufacturing operations.

Key Terms

Takt Time

Assembly line balancers optimize production efficiency by adjusting workstations to meet specific Takt Time targets, ensuring each task aligns with customer demand rhythms. They analyze cycle times and redistribute workloads to minimize bottlenecks and idle time, directly impacting overall throughput and quality levels. Mastery of Takt Time enables assembly line balancers to harmonize workflow and maintain steady, predictable manufacturing output.

Workstation Efficiency

Assembly line balancers optimize workstation efficiency by analyzing task times and redistributing workloads to minimize bottlenecks and idle time. They use time studies and workflow analysis to ensure balanced task allocation, resulting in smoother production flow and increased throughput. Their role directly impacts productivity by reducing cycle time and enhancing overall assembly line performance.

Line Balancing

Assembly line balancers optimize production efficiency by distributing tasks evenly across workstations to minimize idle time and bottlenecks. They analyze workflow data, calculate task durations, and adjust station assignments to ensure smooth operation and maximize throughput. Expertise in industrial engineering principles and real-time analytics tools is essential for effective line balancing and continuous process improvement.

Bottleneck

An assembly line balancer identifies bottlenecks in production workflows to optimize efficiency and reduce delays. By analyzing task durations and reallocating resources, they ensure smooth, continuous output and minimize idle time. Expertise in workflow analysis and time management tools is critical for addressing bottleneck issues effectively.

kuljobs.com

kuljobs.com