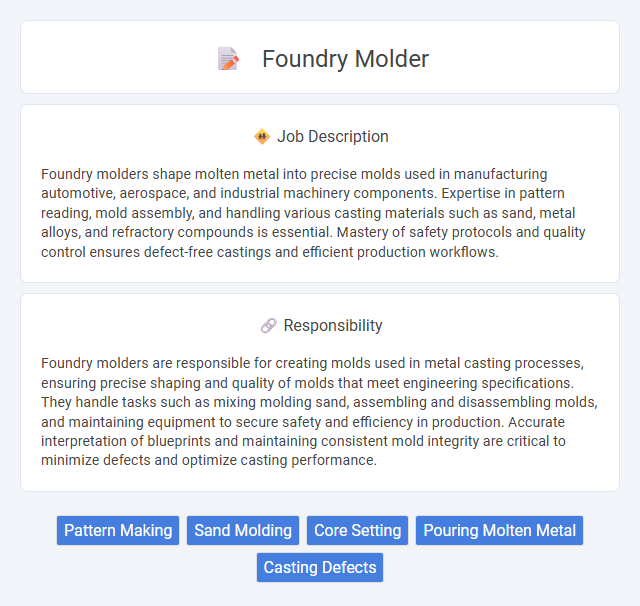

Foundry molders shape molten metal into precise molds used in manufacturing automotive, aerospace, and industrial machinery components. Expertise in pattern reading, mold assembly, and handling various casting materials such as sand, metal alloys, and refractory compounds is essential. Mastery of safety protocols and quality control ensures defect-free castings and efficient production workflows.

Foundry molder jobs often require individuals with physical stamina and the ability to work in hot, dusty environments, which may not be suitable for those with respiratory issues or limited mobility. This role probably suits people who are detail-oriented and comfortable handling heavy molds and machinery under pressure. Candidates lacking strength or endurance might find the job challenging to perform consistently.

Qualification

A Foundry Molder requires proficiency in interpreting blueprints and molds with an emphasis on precision and safety standards. Candidates must have hands-on experience in preparing casting sand mixtures and operating molding machines to ensure quality metal castings. Strong knowledge of metallurgy, mechanical aptitude, and adherence to environmental regulations are essential qualifications for this role.

Responsibility

Foundry molders are responsible for creating molds used in metal casting processes, ensuring precise shaping and quality of molds that meet engineering specifications. They handle tasks such as mixing molding sand, assembling and disassembling molds, and maintaining equipment to secure safety and efficiency in production. Accurate interpretation of blueprints and maintaining consistent mold integrity are critical to minimize defects and optimize casting performance.

Benefit

Foundry molders likely enjoy benefits such as competitive wages and comprehensive health insurance plans that support their well-being. Opportunities for overtime pay and skill development training may increase overall earning potential and job security. Employers might also provide retirement plans and workplace safety programs, contributing to long-term financial stability and a safer working environment.

Challenge

Foundry molder jobs likely present significant challenges due to the physical demands and precision required in shaping molten metal. The risk of exposure to high temperatures and heavy machinery may contribute to workplace hazards. Mastery of complex molding techniques could require extensive training and continuous skill development.

Career Advancement

Foundry molders with advanced skills in pattern making and core setting can progress to supervisory or quality control roles within manufacturing plants. Mastery of casting techniques and metal properties enhances opportunities for specialization in precision foundry work or process optimization. Continuous training in computer-aided design (CAD) and automation tools significantly boosts career growth prospects and salary potential.

Key Terms

Pattern Making

Foundry molders specialize in creating precise molds used for casting metal parts, with a critical skill set centered on pattern making to ensure accurate replication of designs. Expert pattern makers use materials such as wood, plastic, or metal to fabricate detailed patterns that form cavity shapes within sand molds, directly influencing the quality and dimensional accuracy of the final cast product. Proficiency in interpreting blueprints, applying technical drawings, and utilizing CAD software enhances pattern makers' ability to produce complex shapes critical in automotive, aerospace, and heavy machinery foundries.

Sand Molding

Sand molding in foundry molding involves creating molds from sand mixed with binders to form complex metal parts with high precision. Foundry sand molders prepare and maintain sand molds, ensuring correct mold shape, moisture content, and compactness for optimal casting quality. Mastery of sand handling techniques, pattern assembly, and mold inspection significantly impacts casting accuracy and reduces defects in metal production.

Core Setting

A Foundry molder specializing in core setting expertly shapes sand cores, essential for forming internal cavities in metal castings. Precision and skill in core positioning ensure the integrity and accuracy of the final product, directly impacting casting quality. Mastery of various core materials and adhesives enhances mold stability during the metal pour process.

Pouring Molten Metal

Foundry molders specialize in pouring molten metal into molds with precision to create complex metal castings. They monitor temperature and metal flow to ensure optimal consistency and avoid defects such as porosity or cold shuts. Expertise in handling various metals, including iron, aluminum, and bronze, is crucial for maintaining structural integrity and meeting engineering specifications.

Casting Defects

Foundry molders must expertly shape sand molds for metal casting, carefully controlling the sand composition and mold design to prevent casting defects such as porosity, misruns, and cold shuts. Understanding the causes of defects like shrinkage, gas inclusions, and surface blemishes enables molders to adjust patterns and gating systems to ensure defect-free castings. Precision in mold preparation directly impacts the quality and structural integrity of metal components, reducing the need for costly rework and improving production efficiency.

kuljobs.com

kuljobs.com