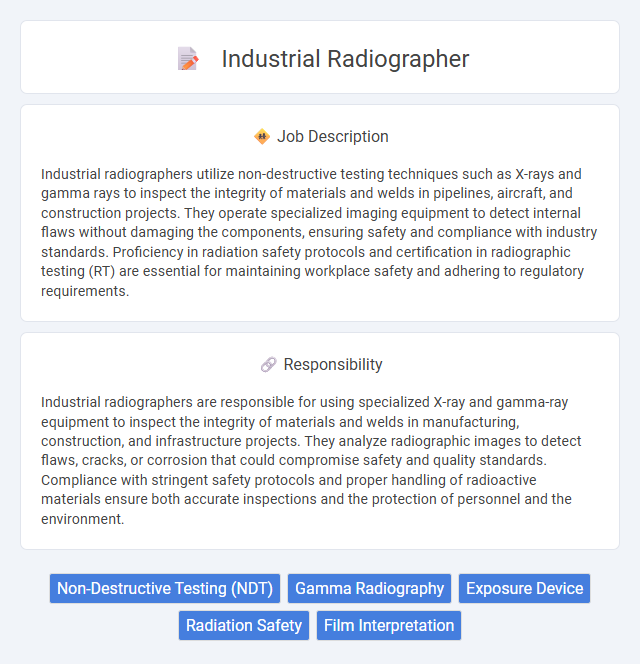

Industrial radiographers utilize non-destructive testing techniques such as X-rays and gamma rays to inspect the integrity of materials and welds in pipelines, aircraft, and construction projects. They operate specialized imaging equipment to detect internal flaws without damaging the components, ensuring safety and compliance with industry standards. Proficiency in radiation safety protocols and certification in radiographic testing (RT) are essential for maintaining workplace safety and adhering to regulatory requirements.

Industrial radiographers often face challenging working conditions that include exposure to radiation, confined spaces, and sometimes harsh outdoor environments, which may affect individuals with certain health concerns or anxiety issues. Those who demonstrate strong attention to detail, physical stamina, and a high level of safety awareness are more likely to be suitable for this role. Individuals who prefer predictable indoor office work or have difficulty adhering to strict safety protocols might find this job less compatible.

Qualification

Industrial radiographers must possess specialized qualifications, typically including a certification or license in non-destructive testing (NDT) or radiography from accredited organizations such as ASNT or IRRSP. A minimum of a high school diploma is required, with many employers preferring candidates with advanced technical training or associate degrees in radiologic technology or related fields. Hands-on experience in industrial environments and knowledge of radiation safety protocols are crucial for ensuring compliance with regulatory standards and effective operation of radiographic equipment.

Responsibility

Industrial radiographers are responsible for using specialized X-ray and gamma-ray equipment to inspect the integrity of materials and welds in manufacturing, construction, and infrastructure projects. They analyze radiographic images to detect flaws, cracks, or corrosion that could compromise safety and quality standards. Compliance with stringent safety protocols and proper handling of radioactive materials ensure both accurate inspections and the protection of personnel and the environment.

Benefit

Industrial radiographer jobs likely offer benefits such as competitive salaries and health insurance due to the specialized nature of the work. There is a probability of gaining valuable experience with advanced imaging technology, which could enhance career advancement opportunities. Employees may also receive comprehensive safety training, reducing occupational risks common in industrial environments.

Challenge

Industrial radiographer jobs likely present significant challenges due to the need for precise handling of radioactive materials and strict adherence to safety protocols. The role probably demands high attention to detail to detect material defects without compromising safety or quality. Managing exposure risks and navigating complex environments likely require continuous training and vigilance.

Career Advancement

Industrial radiographers use non-destructive testing techniques to inspect materials and structures for internal defects, ensuring safety and quality in industries such as oil and gas, construction, and manufacturing. Career advancement often involves gaining certifications like ASNT Level II or III and specializing in advanced imaging technologies, leading to roles like senior radiographer or NDT manager. Continuous training and experience in radiation safety, advanced radiographic techniques, and quality control enhance opportunities for leadership positions and higher salaries.

Key Terms

Non-Destructive Testing (NDT)

Industrial radiographers specialize in Non-Destructive Testing (NDT) methods to inspect the integrity of materials and structures using X-rays, gamma rays, or other imaging technologies. They detect flaws, cracks, or corrosion in pipelines, welds, and metal components without causing damage, ensuring safety and compliance in industries such as oil and gas, manufacturing, and construction. Proficiency in radiation safety protocols and advanced imaging techniques is essential for accurate diagnostics and preventing hazardous exposure.

Gamma Radiography

Industrial radiographers specializing in gamma radiography use gamma radiation to inspect the integrity of metal structures, pipelines, and welds in manufacturing and construction industries. Utilizing isotopes such as Iridium-192 or Cobalt-60, they produce detailed radiographic images that reveal internal defects like cracks, corrosion, and voids without damaging the material. Proficiency in radiation safety protocols and interpretation of radiographic films is crucial to ensure accurate diagnostics and protect both personnel and equipment.

Exposure Device

An industrial radiographer operates exposure devices to perform non-destructive testing using gamma or X-ray sources, ensuring the integrity of materials and welds in construction, manufacturing, and petroleum industries. Expert handling and precise calibration of exposure devices are crucial to maintain radiation safety and achieve high-quality radiographic images that reveal internal flaws or defects. Strict adherence to safety protocols and regulations protects both the operator and the environment from harmful radiation exposure during inspections.

Radiation Safety

Industrial radiographers use specialized equipment to inspect materials for structural integrity through non-destructive testing methods involving ionizing radiation. Ensuring radiation safety is critical, requiring strict adherence to regulatory standards, use of proper shielding, personal protective equipment, and continuous monitoring of radiation exposure levels. Effective safety protocols minimize risks to operators and surrounding personnel, preventing harmful radiation exposure and maintaining workplace health compliance.

Film Interpretation

Industrial radiographers specialize in non-destructive testing by analyzing radiographic films to detect flaws in materials such as metal welds and pipelines. Precise film interpretation requires expertise in identifying density variations, cracks, porosity, and inclusions that may compromise structural integrity. Mastery of advanced imaging techniques and adherence to safety protocols ensure accurate assessments and reliable results in quality control inspections.

kuljobs.com

kuljobs.com