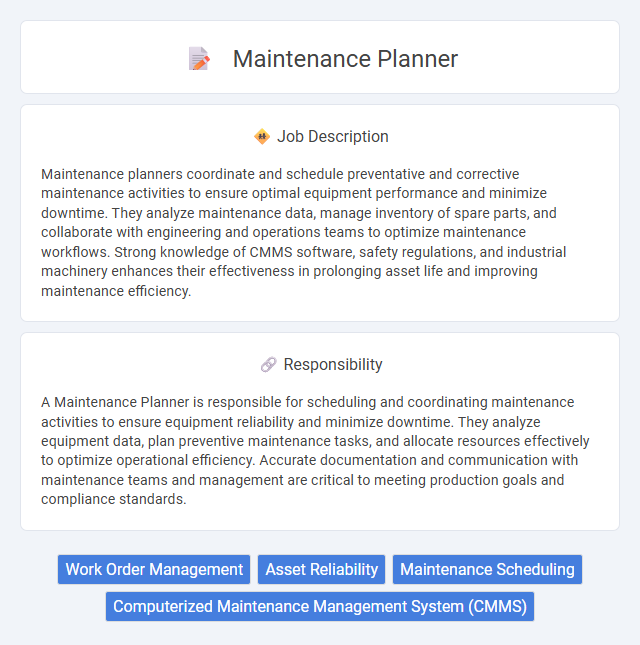

Maintenance planners coordinate and schedule preventative and corrective maintenance activities to ensure optimal equipment performance and minimize downtime. They analyze maintenance data, manage inventory of spare parts, and collaborate with engineering and operations teams to optimize maintenance workflows. Strong knowledge of CMMS software, safety regulations, and industrial machinery enhances their effectiveness in prolonging asset life and improving maintenance efficiency.

Individuals who possess strong organizational skills and attention to detail are likely to be well-suited for a Maintenance Planner role, as the job demands precise scheduling and coordination of maintenance activities. Those who handle stress poorly or struggle with multitasking may find the position challenging due to its dynamic and deadline-driven nature. Candidates with a proactive mindset and good communication abilities probably stand a higher chance of success in effectively managing maintenance workflows and collaborating with various teams.

Qualification

A Maintenance Planner must possess strong technical knowledge in mechanical, electrical, or industrial engineering, combined with experience in preventive and corrective maintenance scheduling. Proficiency in using Computerized Maintenance Management Systems (CMMS) and project management software is essential for optimizing maintenance workflows and minimizing downtime. Strong analytical, organizational, and communication skills ensure the ability to coordinate resources efficiently and support operational reliability.

Responsibility

A Maintenance Planner is responsible for scheduling and coordinating maintenance activities to ensure equipment reliability and minimize downtime. They analyze equipment data, plan preventive maintenance tasks, and allocate resources effectively to optimize operational efficiency. Accurate documentation and communication with maintenance teams and management are critical to meeting production goals and compliance standards.

Benefit

Maintenance planner roles likely offer benefits such as enhanced operational efficiency and reduced equipment downtime, which may lead to cost savings for organizations. Employees in this position probably experience improved project coordination and resource management skills, increasing their professional value. Access to structured maintenance schedules and predictive tools might contribute to a safer work environment and longer equipment lifespan.

Challenge

A Maintenance Planner likely encounters the challenge of balancing precise scheduling with unexpected equipment failures, which may require rapid adjustments to minimize downtime. The role probably demands strong analytical skills to predict maintenance needs accurately, reducing the risk of costly interruptions. High-pressure situations and coordination across multiple teams might often test the planner's ability to prioritize tasks effectively.

Career Advancement

Maintenance planners play a crucial role in optimizing equipment reliability and reducing downtime in manufacturing and industrial sectors. Mastery in predictive maintenance technologies and advanced CMMS software enhances career prospects, enabling progression to maintenance manager or reliability engineer positions. Continuous skill development in strategic asset management and leadership fosters long-term advancement and higher salary potential.

Key Terms

Work Order Management

Maintenance planners excel in Work Order Management by efficiently scheduling and coordinating tasks to maximize equipment uptime and reduce downtime. They create detailed work orders that include necessary resources, labor allocation, and timelines to ensure seamless execution. Their expertise in tracking work order progress and updating maintenance records optimizes asset reliability and operational efficiency.

Asset Reliability

A Maintenance Planner specializing in Asset Reliability ensures optimal performance and longevity of critical equipment by scheduling preventive and predictive maintenance activities. They analyze asset performance data, failure modes, and maintenance histories to develop strategic plans that minimize downtime and maximize operational efficiency. Collaboration with engineering and operations teams enables continuous improvement in maintenance processes and asset reliability metrics.

Maintenance Scheduling

A Maintenance Planner specializing in Maintenance Scheduling coordinates and optimizes maintenance activities to ensure minimal downtime and efficient resource allocation. Utilizing software tools like CMMS (Computerized Maintenance Management Systems), they develop detailed schedules that align with production demands and equipment availability. Their role includes forecasting maintenance needs, prioritizing tasks, and collaborating with maintenance teams to enhance operational reliability and extend asset life.

Computerized Maintenance Management System (CMMS)

Maintenance planners utilize Computerized Maintenance Management Systems (CMMS) to schedule, track, and optimize maintenance activities, ensuring maximum equipment uptime and operational efficiency. They analyze data from the CMMS to forecast maintenance needs, allocate resources, and manage work orders effectively. Proficiency in CMMS software like SAP PM, Maximo, or Infor EAM is critical for accurate planning and reducing unplanned downtime.

kuljobs.com

kuljobs.com