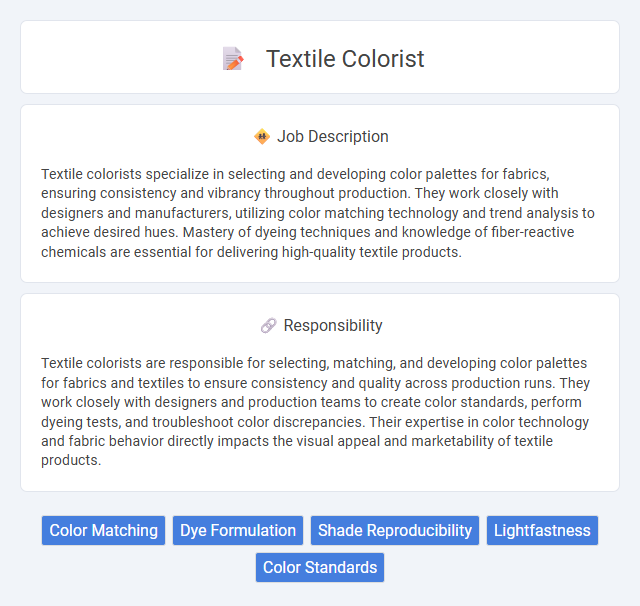

Textile colorists specialize in selecting and developing color palettes for fabrics, ensuring consistency and vibrancy throughout production. They work closely with designers and manufacturers, utilizing color matching technology and trend analysis to achieve desired hues. Mastery of dyeing techniques and knowledge of fiber-reactive chemicals are essential for delivering high-quality textile products.

Individuals with a keen eye for color and detail are likely to excel as textile colorists, as this role demands precision in matching and creating fabric hues. People who enjoy experimenting with shades and have patience for repetitive tasks could find this career fulfilling and well-suited to their temperament. Those with color vision deficiencies or a dislike for meticulous work might face challenges in this profession.

Qualification

A textile colorist must possess a strong understanding of color theory, fabric types, and dyeing techniques to ensure accurate color matching and consistency. Proficiency in using color measurement tools and software, combined with a background in chemistry or textile design, is essential for analyzing pigments and developing custom color solutions. Attention to detail, creativity, and experience with industry standards like Pantone color systems significantly enhance a colorist's ability to deliver high-quality textile products.

Responsibility

Textile colorists are responsible for selecting, matching, and developing color palettes for fabrics and textiles to ensure consistency and quality across production runs. They work closely with designers and production teams to create color standards, perform dyeing tests, and troubleshoot color discrepancies. Their expertise in color technology and fabric behavior directly impacts the visual appeal and marketability of textile products.

Benefit

A textile colorist likely enhances the visual appeal of fabrics by selecting and applying precise color palettes, which could increase product marketability and customer satisfaction. Their expertise may contribute to reducing waste and production costs through accurate color matching, improving overall efficiency. Employers probably benefit from their ability to maintain brand consistency and innovate with trending colors, supporting competitive advantage.

Challenge

The role of a textile colorist likely involves the challenge of accurately predicting how colors will appear on different fabric types and under various lighting conditions. There is a probability of encountering difficulties in maintaining color consistency across large production batches, which requires precise calibration and quality control. Adapting to rapidly changing fashion trends and customer preferences could also present ongoing complexities demanding creativity and technical expertise.

Career Advancement

Textile colorists enhance fabric aesthetics by expertly selecting and matching colors, playing a critical role in the fashion and manufacturing industries. Career advancement opportunities include becoming senior colorists, color managers, or moving into textile design and product development roles. Mastery of advanced color technologies and industry trends significantly boosts prospects for leadership positions and specialization in sustainable and digital textile printing.

Key Terms

Color Matching

Textile colorists specialize in precise color matching to ensure fabric hues meet exact customer specifications and batch consistency. They utilize advanced spectrophotometers and computer-aided dyeing systems for accurate shade reproduction across different textile materials. Mastery in pigment formulation and fabric testing enables textile colorists to maintain colorfastness and quality standards in production.

Dye Formulation

Textile colorists specializing in dye formulation develop precise color recipes ensuring consistent and vibrant fabric hues across production batches. Their expertise combines chemistry knowledge with material science to select appropriate dyes, auxiliaries, and fixation methods tailored to specific textile fibers. Mastery of color matching software and advanced spectrophotometers enables accurate reproduction of shades, optimizing dye uptake and minimizing waste during manufacturing processes.

Shade Reproducibility

Shade reproducibility is a critical skill for textile colorists, ensuring consistent color matching across different fabric batches and production runs. Precise color measurement tools and standardized lighting conditions enable colorists to replicate exact shades, maintaining brand integrity and customer satisfaction. Mastery in shade reproducibility reduces waste and production delays by minimizing color variation in textile manufacturing.

Lightfastness

A textile colorist specializes in creating and selecting dyes and pigments that ensure vibrant, long-lasting colors with optimal lightfastness, preventing fading under exposure to sunlight. Mastery of lightfastness testing methods such as Xenon arc or UV chamber assessments is crucial to guarantee durability and customer satisfaction. Expertise in chemical formulations and fiber compatibility enhances the ability to deliver textiles that maintain color integrity across various lighting conditions.

Color Standards

Textile colorists specialize in creating and maintaining precise color standards for fabrics, ensuring consistency across production batches. They use advanced spectrophotometers and color measurement tools to match dye formulas with industry-specific color references such as Pantone and AATCC standards. Their expertise directly influences product quality and brand integrity by minimizing color variation in textiles during manufacturing processes.

kuljobs.com

kuljobs.com