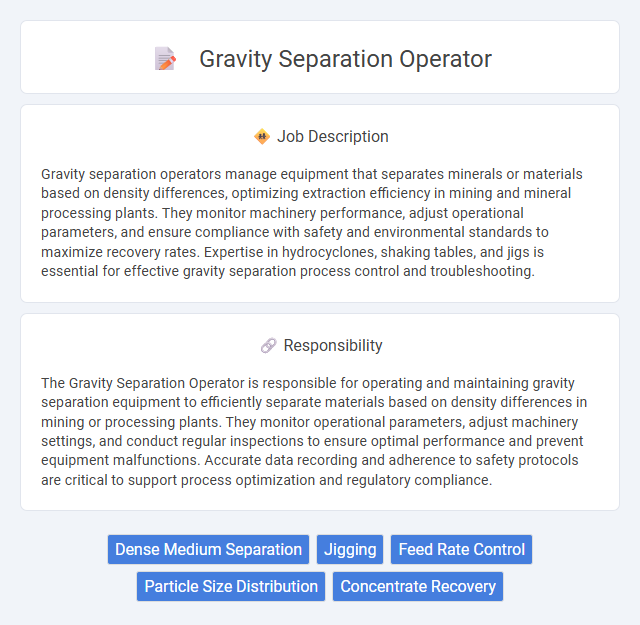

Gravity separation operators manage equipment that separates minerals or materials based on density differences, optimizing extraction efficiency in mining and mineral processing plants. They monitor machinery performance, adjust operational parameters, and ensure compliance with safety and environmental standards to maximize recovery rates. Expertise in hydrocyclones, shaking tables, and jigs is essential for effective gravity separation process control and troubleshooting.

Individuals with good physical stamina and the ability to work in potentially noisy, industrial environments may be suitable for a Gravity Separation Operator role. Those comfortable with operating heavy machinery and following safety protocols likely have a higher probability of success. People who prefer sedentary work or have difficulty adapting to physically demanding tasks may not be as well suited for this position.

Qualification

A Gravity Separation Operator must possess a strong background in mining engineering or mineral processing, typically requiring a diploma or degree in these fields. Proficiency in operating gravity separation equipment such as jigs, spirals, and shaking tables is essential, alongside knowledge of ore characteristics and gravity concentration principles. Certification in occupational safety and experience in monitoring separation efficiency and equipment maintenance significantly enhance job performance.

Responsibility

The Gravity Separation Operator is responsible for operating and maintaining gravity separation equipment to efficiently separate materials based on density differences in mining or processing plants. They monitor operational parameters, adjust machinery settings, and conduct regular inspections to ensure optimal performance and prevent equipment malfunctions. Accurate data recording and adherence to safety protocols are critical to support process optimization and regulatory compliance.

Benefit

Gravity separation operators likely improve material recovery rates by efficiently separating particles based on density differences, enhancing overall processing accuracy and cost-effectiveness. Their role may reduce energy consumption and minimize the need for chemical reagents, contributing to more sustainable operations. Efficiency gains from precise gravity separation could increase production throughput, potentially boosting profitability and operational reliability.

Challenge

Gravity Separation Operators may face challenges such as managing variations in feed material density and moisture content that affect separation efficiency. Equipment calibration and maintenance could require constant attention to ensure consistent performance under fluctuating operating conditions. Operators might also need to quickly adapt to unexpected process disturbances to minimize downtime and maintain product quality.

Career Advancement

Gravity Separation Operators play a crucial role in mineral processing plants by optimizing equipment that separates materials based on density differences. Expertise in operating and maintaining gravity concentrators, jig separators, and spirals enhances efficiency and material recovery rates, positioning professionals for senior technical or supervisory roles. Gaining certifications in mineral processing techniques and leadership skills further accelerates career advancement opportunities within mining and metallurgical industries.

Key Terms

Dense Medium Separation

The Gravity Separation Operator specializes in Dense Medium Separation (DMS) to efficiently separate ore particles based on density differences, enhancing mineral recovery and purity. This role involves maintaining and optimizing the DMS plant, monitoring slurry density, and adjusting magnetite media to maximize separation accuracy. Proficiency in process control, equipment troubleshooting, and safety adherence ensures consistent plant performance and operational excellence.

Jigging

A Gravity Separation Operator specializing in jigging manages the separation of mineral particles based on density differences using a jigging machine. This role involves controlling water flow rates, pulsation frequency, and feed distribution to optimize the recovery of heavy metals and minerals. Proficiency in monitoring equipment performance and adjusting operational parameters ensures maximum efficiency and concentrate quality in ore processing.

Feed Rate Control

Gravity separation operators expertly manage feed rate control to optimize the efficiency of mineral processing operations. Precise adjustment of feed rates ensures consistent material flow, enhancing separation accuracy and recovery rates of valuable minerals. Mastery in monitoring feed parameters minimizes equipment wear and optimizes throughput in concentration circuits.

Particle Size Distribution

Gravity Separation Operators specialize in optimizing particle size distribution to enhance mineral processing efficiency. Precise control over feed and discharge particle sizes directly influences separation performance by maximizing the recovery of target minerals and minimizing waste. Understanding the impact of particle size on settling rates and separation dynamics is crucial for achieving consistent product quality in gravity concentration circuits.

Concentrate Recovery

Gravity Separation Operators specialize in optimizing mineral concentrate recovery by utilizing gravity-based equipment such as jigs, spirals, and shaking tables. They monitor and adjust process parameters to maximize the extraction of valuable minerals from ore concentrates, ensuring high yield and grade. Expertise in mineralogy and process control enhances the efficiency and profitability of concentrate recovery operations.

kuljobs.com

kuljobs.com