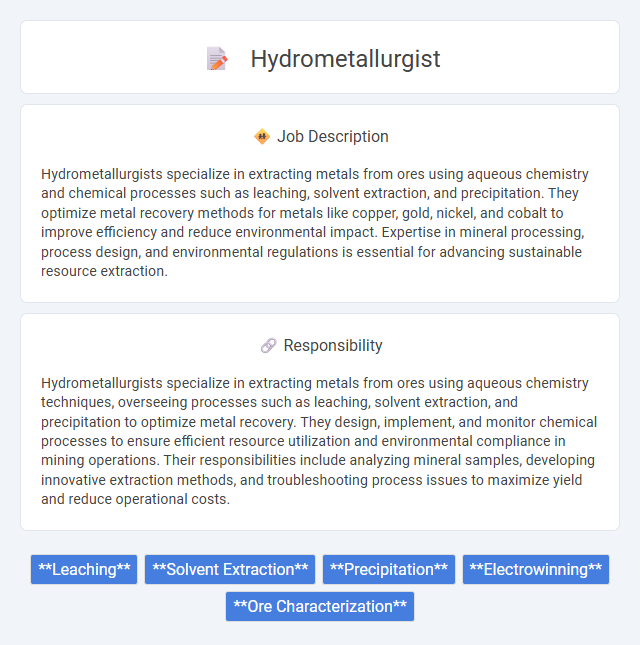

Hydrometallurgists specialize in extracting metals from ores using aqueous chemistry and chemical processes such as leaching, solvent extraction, and precipitation. They optimize metal recovery methods for metals like copper, gold, nickel, and cobalt to improve efficiency and reduce environmental impact. Expertise in mineral processing, process design, and environmental regulations is essential for advancing sustainable resource extraction.

Individuals with strong analytical skills and a background in chemistry or metallurgy are likely to excel as hydrometallurgists, given the technical nature of the job. Those who enjoy problem-solving in laboratory or industrial settings might find this career fulfilling, while candidates who prefer less detail-oriented or physically demanding work may struggle. It is probable that individuals comfortable with working around chemicals and adhering to safety protocols will suit this role best.

Qualification

A Hydrometallurgist typically requires a degree in metallurgical engineering, chemical engineering, or materials science, with specialized coursework in hydrometallurgy processes such as leaching, solvent extraction, and precipitation. Professional qualifications often include experience with mineral processing plants and proficiency in simulation software like HSC Chemistry or METSIM. Advanced roles may demand certifications in project management or environmental compliance to enhance operational efficiency and adherence to safety standards.

Responsibility

Hydrometallurgists specialize in extracting metals from ores using aqueous chemistry techniques, overseeing processes such as leaching, solvent extraction, and precipitation to optimize metal recovery. They design, implement, and monitor chemical processes to ensure efficient resource utilization and environmental compliance in mining operations. Their responsibilities include analyzing mineral samples, developing innovative extraction methods, and troubleshooting process issues to maximize yield and reduce operational costs.

Benefit

Working as a hydrometallurgist likely offers significant benefits such as specialized expertise in extracting metals through aqueous chemistry, which may lead to high demand in mining and metallurgical industries. The role probably provides opportunities for career advancement and involvement in environmentally friendly metal recovery techniques. Salary potential and job stability might be attractive due to the technical nature of the work and its importance in resource management.

Challenge

A Hydrometallurgist likely faces challenges in optimizing extraction processes for complex ores, where variable mineral compositions demand precise chemical adjustments to maximize recovery rates. The probability of encountering environmental concerns is high, requiring innovative solutions to minimize waste and ensure sustainable operations. Adapting to evolving technologies and regulations could also present ongoing challenges in this role.

Career Advancement

Hydrometallurgists specializing in extracting metals through aqueous chemistry progressively advance by mastering process optimization and innovation in solvent extraction, leaching, and precipitation techniques. Career growth often leads to senior roles such as process engineer, project manager, or technical director within mining, metallurgical, and environmental industries. Proficiency in simulation software and regulatory compliance further enhances opportunities for leadership positions and consultancy in sustainable metal recovery.

Key Terms

Leaching

Hydrometallurgists specialize in leaching techniques to extract valuable metals from ores using aqueous chemistry processes. Efficient leaching methods such as heap leaching, pressure leaching, and tank leaching optimize metal recovery rates for copper, gold, nickel, and uranium. Understanding chemical reactions and fluid dynamics during leaching is crucial for improving metal extraction efficiency and minimizing environmental impact.

Solvent Extraction

Hydrometallurgists specializing in solvent extraction design and optimize processes to separate valuable metals from ores using selective solvents. Expertise in solvent extraction involves controlling phase equilibria and reagent chemistry to maximize metal recovery and purity, particularly for copper, nickel, and cobalt production. Mastery of mixer-settler operations and continuous extraction techniques is crucial for improving efficiency and reducing environmental impact in hydrometallurgical plants.

Precipitation

Hydrometallurgists specialize in the precipitation process to extract metals from aqueous solutions, optimizing chemical reactions to convert dissolved metal ions into solid compounds. This technique is crucial for recovering valuable metals such as copper, nickel, and zinc from leachates in mining operations. Mastery of precipitation parameters, including pH, temperature, and reagent concentration, directly impacts metal recovery rates and process efficiency.

Electrowinning

Hydrometallurgists specializing in electrowinning design and optimize processes to recover metals like copper, gold, and zinc from aqueous solutions through electrochemical deposition. Their expertise ensures efficient metal extraction, improved product purity, and energy conservation in electrowinning cells, crucial for sustainable metallurgy operations. Advanced knowledge of electrolyte chemistry, electrode materials, and cell design enables hydrometallurgists to enhance recovery rates and reduce operational costs in metal beneficiation.

Ore Characterization

Hydrometallurgists specializing in ore characterization analyze the physical and chemical properties of ores to determine the most efficient extraction methods. They utilize techniques such as mineralogical analysis, leaching tests, and particle size distribution to optimize hydrometallurgical processing. Accurate ore characterization is crucial for improving metal recovery rates and reducing processing costs in operations involving copper, gold, nickel, and other valuable minerals.

kuljobs.com

kuljobs.com