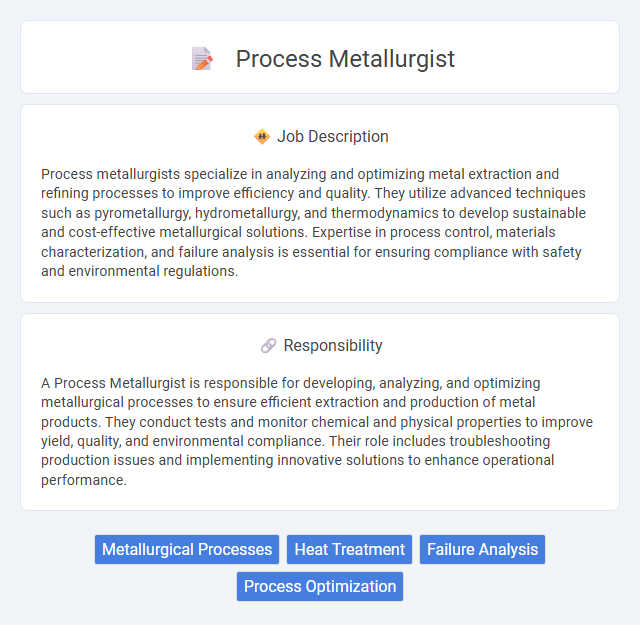

Process metallurgists specialize in analyzing and optimizing metal extraction and refining processes to improve efficiency and quality. They utilize advanced techniques such as pyrometallurgy, hydrometallurgy, and thermodynamics to develop sustainable and cost-effective metallurgical solutions. Expertise in process control, materials characterization, and failure analysis is essential for ensuring compliance with safety and environmental regulations.

Individuals with strong analytical skills and an interest in chemistry and materials science are likely suitable for a Process Metallurgist role. Candidates who tolerate working in industrial environments and are comfortable with detailed monitoring and optimization tasks might find this job fitting. Those preferring routine or less technical work may have difficulty adapting to the demands of process metallurgy.

Qualification

A Process Metallurgist typically requires a Bachelor's degree in Metallurgy, Materials Science, or Chemical Engineering, with specialization in extractive metallurgy or mineral processing. Proficiency in process optimization, quality control, and the use of metallurgical testing equipment is essential. Advanced knowledge of smelting, refining techniques, and experience with software for process simulation enhances job performance and qualifications.

Responsibility

A Process Metallurgist is responsible for developing, analyzing, and optimizing metallurgical processes to ensure efficient extraction and production of metal products. They conduct tests and monitor chemical and physical properties to improve yield, quality, and environmental compliance. Their role includes troubleshooting production issues and implementing innovative solutions to enhance operational performance.

Benefit

Process Metallurgists likely benefit from high demand in industries such as mining, manufacturing, and materials development, offering stable employment prospects. They probably enjoy opportunities for professional growth due to advancements in metallurgical technologies and processes. Competitive salaries and involvement in innovative projects may further enhance the overall job satisfaction in this field.

Challenge

A Process Metallurgist likely faces the challenge of optimizing metallurgical processes to balance quality, efficiency, and cost-effectiveness while adapting to new materials and evolving industry standards. They may encounter difficulties in troubleshooting complex production issues and implementing innovative solutions under strict safety and environmental regulations. Success in this role probably requires strong analytical skills and the ability to manage uncertainties in process variables.

Career Advancement

Process metallurgists enhance their expertise by mastering advanced materials characterization and process optimization techniques, positioning themselves for leadership roles in research and production management. Gaining certifications in quality control and Six Sigma methodologies accelerates career progression toward senior engineer or metallurgical consultant positions. Networking through industry associations such as TMS and continuous learning of emerging metallurgical technologies further supports advancement into strategic decision-making and executive roles.

Key Terms

Metallurgical Processes

Process metallurgists specialize in optimizing metallurgical processes such as melting, casting, and alloying to enhance metal quality and production efficiency. They analyze material properties and control variables like temperature, chemical composition, and cooling rates to achieve desired metallurgical outcomes. Expertise in process simulation, quality testing, and failure analysis ensures continuous improvement in metal manufacturing operations.

Heat Treatment

Process Metallurgists specializing in heat treatment optimize the thermal cycles to enhance material properties such as hardness, strength, and toughness in metals and alloys. They analyze microstructures and control parameters like temperature, time, and cooling rates to ensure compliance with industry standards and improve product performance. Advanced knowledge of phase transformations and metallurgical phenomena is critical for developing efficient heat treatment processes in automotive, aerospace, and manufacturing sectors.

Failure Analysis

A Process Metallurgist specializing in failure analysis investigates material defects and breakdowns to identify root causes affecting metallurgical processes. They utilize techniques such as microscopy, spectroscopy, and mechanical testing to analyze failures in metals and alloys, ensuring quality control and process optimization. Their findings drive improvements in manufacturing protocols, reducing production downtime and enhancing component reliability.

Process Optimization

Process Metallurgists specialize in optimizing metal extraction and refining methods to enhance efficiency, reduce costs, and improve product quality. They analyze metallurgical data, troubleshoot production issues, and implement improvements in processes such as smelting, casting, and heat treatment. Leveraging advanced metallurgical techniques and process simulations, they ensure sustainable and scalable operations in mining and manufacturing industries.

kuljobs.com

kuljobs.com