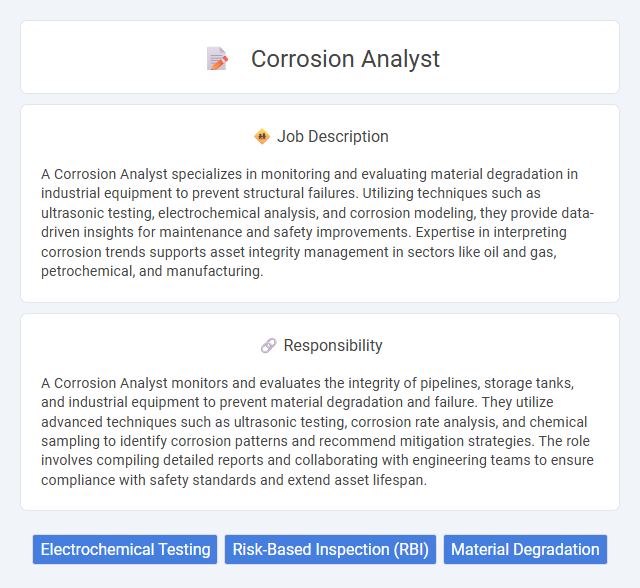

A Corrosion Analyst specializes in monitoring and evaluating material degradation in industrial equipment to prevent structural failures. Utilizing techniques such as ultrasonic testing, electrochemical analysis, and corrosion modeling, they provide data-driven insights for maintenance and safety improvements. Expertise in interpreting corrosion trends supports asset integrity management in sectors like oil and gas, petrochemical, and manufacturing.

Individuals with strong analytical skills and a keen attention to detail are likely to be well-suited for a Corrosion Analyst role. Those who enjoy working with data, conducting inspections, and applying scientific principles to assess material degradation may find this career fulfilling. Candidates who prefer hands-on problem-solving and can tolerate working in industrial environments might also have a higher probability of success in this position.

Qualification

A Corrosion Analyst requires a strong background in materials science, chemistry, or chemical engineering, with proficiency in corrosion testing methods and failure analysis techniques. Certification such as NACE Coating Inspector or Corrosion Technologist enhances credibility and industry recognition. Experience with corrosion monitoring tools, data interpretation, and compliance with safety and environmental standards is essential for effective risk assessment and mitigation.

Responsibility

A Corrosion Analyst monitors and evaluates the integrity of pipelines, storage tanks, and industrial equipment to prevent material degradation and failure. They utilize advanced techniques such as ultrasonic testing, corrosion rate analysis, and chemical sampling to identify corrosion patterns and recommend mitigation strategies. The role involves compiling detailed reports and collaborating with engineering teams to ensure compliance with safety standards and extend asset lifespan.

Benefit

Corrosion analysts likely contribute to extending the lifespan of critical infrastructure by accurately predicting material degradation. Their expertise probably reduces maintenance costs and enhances safety measures across industries such as oil and gas or manufacturing. Working in this role might also offer opportunities for professional growth in materials science and engineering fields.

Challenge

Corrosion Analyst roles likely present the challenge of accurately predicting material degradation in complex environments, requiring strong analytical and technical skills. The job probably involves interpreting data from varied sources to anticipate corrosion risks and recommend prevention strategies. Successfully managing these challenges is essential for ensuring the longevity and safety of infrastructure and equipment.

Career Advancement

A Corrosion Analyst plays a vital role in identifying and mitigating corrosion risks in industrial environments, directly contributing to asset integrity and safety. Expertise in advanced corrosion monitoring techniques and data interpretation opens pathways to senior technical roles, such as Corrosion Engineer or Asset Integrity Manager. Continuous professional development in materials science and industry standards accelerates career progression in sectors like oil and gas, petrochemicals, and infrastructure management.

Key Terms

Electrochemical Testing

A Corrosion Analyst specializing in electrochemical testing conducts precise evaluations using techniques such as potentiodynamic polarization, electrochemical impedance spectroscopy (EIS), and linear polarization resistance (LPR) to assess material degradation rates. This role involves interpreting data to determine corrosion mechanisms and predict service life of metals in various environments, essential for maintaining structural integrity in industries like oil and gas, aerospace, and marine. Expertise in setting up controlled electrochemical cells and analyzing electrode potentials supports the development of corrosion mitigation strategies and advanced protective coatings.

Risk-Based Inspection (RBI)

A Corrosion Analyst specializing in Risk-Based Inspection (RBI) evaluates the integrity of industrial assets by assessing corrosion risks to prioritize inspection and maintenance activities. Utilizing RBI methodologies, they analyze material degradation, operating conditions, and corrosion mechanisms to optimize inspection intervals and mitigate potential failures. This approach enhances asset reliability, reduces downtime, and supports cost-effective corrosion management in sectors such as oil and gas, petrochemical, and power generation.

Material Degradation

Corrosion analysts specialize in assessing and mitigating material degradation in infrastructure and industrial equipment by analyzing chemical, physical, and environmental factors that accelerate corrosion. They utilize advanced testing methodologies and corrosion modeling software to predict material lifespan and recommend protective measures such as coatings, inhibitors, and cathodic protection systems. Their expertise supports maintenance planning and risk management in sectors like oil and gas, petrochemical, and manufacturing, ensuring operational safety and cost efficiency.

kuljobs.com

kuljobs.com