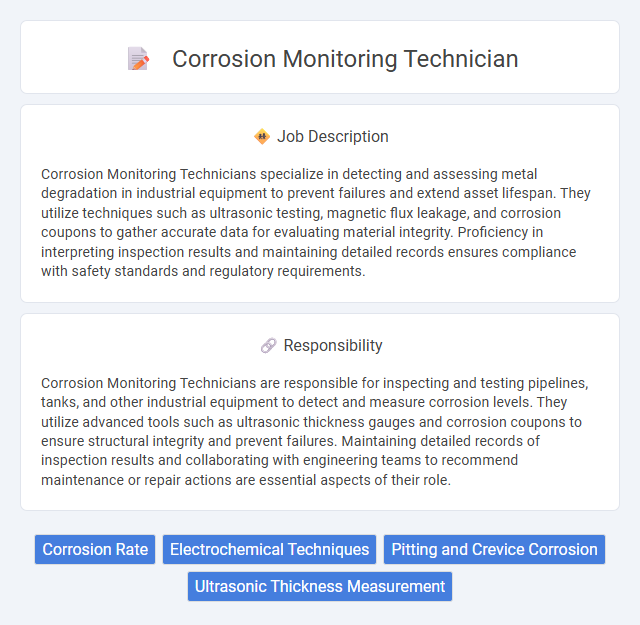

Corrosion Monitoring Technicians specialize in detecting and assessing metal degradation in industrial equipment to prevent failures and extend asset lifespan. They utilize techniques such as ultrasonic testing, magnetic flux leakage, and corrosion coupons to gather accurate data for evaluating material integrity. Proficiency in interpreting inspection results and maintaining detailed records ensures compliance with safety standards and regulatory requirements.

Individuals with strong analytical skills and attention to detail are likely to excel as Corrosion Monitoring Technicians. Those comfortable working in industrial or outdoor environments, often in challenging conditions, may find this role suitable. Candidates who prefer routine inspections combined with data interpretation probably fit well with the responsibilities of this job.

Qualification

Corrosion Monitoring Technicians require a solid foundation in materials science and engineering principles, often holding certifications such as NACE CP1 or equivalent. Experience with ultrasonic testing, ultrasonic thickness measurement, and corrosion rate monitoring tools is essential to ensure accurate data collection and analysis. Strong knowledge of safety protocols and the ability to interpret inspection reports enhances their capability to prevent equipment failure in industrial environments.

Responsibility

Corrosion Monitoring Technicians are responsible for inspecting and testing pipelines, tanks, and other industrial equipment to detect and measure corrosion levels. They utilize advanced tools such as ultrasonic thickness gauges and corrosion coupons to ensure structural integrity and prevent failures. Maintaining detailed records of inspection results and collaborating with engineering teams to recommend maintenance or repair actions are essential aspects of their role.

Benefit

Corrosion Monitoring Technicians likely offer significant benefits by preventing costly equipment failures through early detection of corrosion issues. Their expertise probably enhances operational safety and extends the lifespan of industrial assets, reducing downtime and maintenance costs. Companies employing these specialists may experience improved regulatory compliance and increased overall efficiency.

Challenge

Corrosion Monitoring Technicians likely face the challenge of accurately detecting and assessing corrosion in complex industrial environments, where variables can affect measurement precision. The role probably demands continuous adaptation to evolving technologies and standards to ensure effective maintenance and safety. Managing unexpected corrosion issues may require quick problem-solving skills to prevent costly equipment failures.

Career Advancement

Corrosion Monitoring Technicians gain specialized expertise in detecting and preventing material degradation, making them critical assets in industries like oil and gas, petrochemical, and infrastructure. Career advancement opportunities include progressing to roles such as Corrosion Engineer, Inspection Supervisor, or Asset Integrity Manager, often requiring additional certifications like NACE or API. Continuous skill development in non-destructive testing techniques and data analysis enhances prospects for leadership positions and higher salary brackets.

Key Terms

Corrosion Rate

Corrosion Monitoring Technicians specialize in measuring corrosion rates using techniques like ultrasonic thickness testing and electrochemical methods to ensure asset integrity. Accurate corrosion rate data enables predictive maintenance, reducing equipment failure and extending service life in industries such as oil and gas, petrochemical, and marine. Proficiency in analyzing corrosion rate trends and implementing mitigation strategies is critical for preventing costly downtimes and maintaining safety standards.

Electrochemical Techniques

Corrosion Monitoring Technicians specialize in applying electrochemical techniques such as Electrochemical Impedance Spectroscopy (EIS) and Linear Polarization Resistance (LPR) to detect and quantify corrosion rates in metals and alloys. These professionals utilize sensors and probes to perform in-situ measurements, enabling the early identification of corrosion-related degradation in pipelines, tanks, and industrial equipment. Mastery of data interpretation from techniques like Potentiodynamic Polarization and Electrochemical Noise Analysis ensures accurate assessment and maintenance of asset integrity in sectors such as oil and gas, marine, and infrastructure.

Pitting and Crevice Corrosion

Corrosion Monitoring Technicians specialize in detecting and analyzing pitting and crevice corrosion, which are localized forms of metal degradation causing significant structural damage. They use advanced non-destructive testing methods, such as ultrasonic testing and eddy current inspections, to identify early-stage corrosion hotspots in critical infrastructure like pipelines and storage tanks. Continuous monitoring and precise data analysis enable proactive maintenance strategies, extending asset life and ensuring operational safety.

Ultrasonic Thickness Measurement

Corrosion Monitoring Technicians specialize in Ultrasonic Thickness Measurement (UTM) to assess metal corrosion and material degradation in pipelines, tanks, and industrial equipment. They utilize advanced ultrasonic testing equipment to accurately determine metal loss, ensuring the structural integrity and safety of critical infrastructure. Expertise in interpreting UTM data enables proactive maintenance scheduling and prevention of costly failures in oil and gas, petrochemical, and manufacturing industries.

kuljobs.com

kuljobs.com