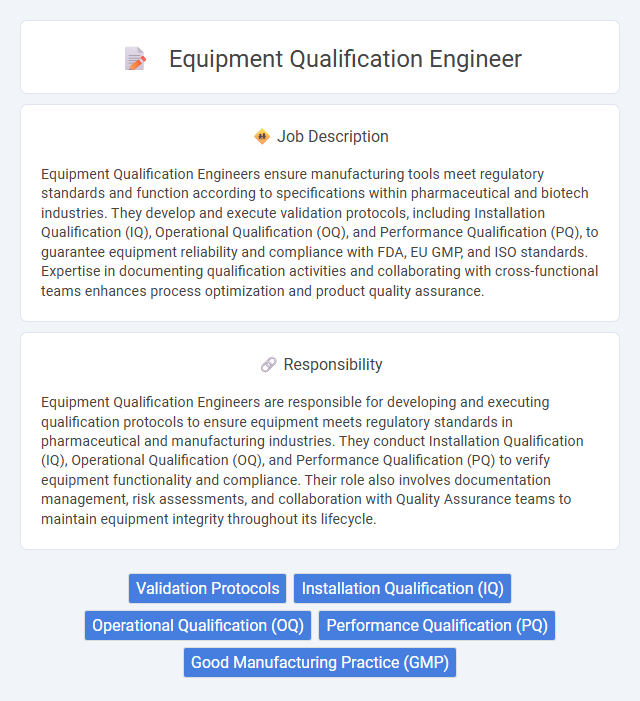

Equipment Qualification Engineers ensure manufacturing tools meet regulatory standards and function according to specifications within pharmaceutical and biotech industries. They develop and execute validation protocols, including Installation Qualification (IQ), Operational Qualification (OQ), and Performance Qualification (PQ), to guarantee equipment reliability and compliance with FDA, EU GMP, and ISO standards. Expertise in documenting qualification activities and collaborating with cross-functional teams enhances process optimization and product quality assurance.

Individuals with strong analytical skills and attention to detail are likely suitable for the Equipment Qualification Engineer role, as it demands precision in assessing equipment performance and compliance. People who thrive in structured environments with strict regulatory requirements may find this position aligns well with their strengths. Conversely, those who struggle with systematic documentation or adapting to technical standards might face challenges in fulfilling the job responsibilities effectively.

Qualification

Equipment Qualification Engineers ensure that manufacturing and laboratory equipment meet rigorous standards for performance, safety, and regulatory compliance through detailed qualification protocols. They develop and execute Installation Qualification (IQ), Operational Qualification (OQ), and Performance Qualification (PQ) procedures to validate equipment functionality and reliability. Their expertise supports regulatory submissions and audits by maintaining thorough documentation and risk assessments aligned with FDA and ISO guidelines.

Responsibility

Equipment Qualification Engineers are responsible for developing and executing qualification protocols to ensure equipment meets regulatory standards in pharmaceutical and manufacturing industries. They conduct Installation Qualification (IQ), Operational Qualification (OQ), and Performance Qualification (PQ) to verify equipment functionality and compliance. Their role also involves documentation management, risk assessments, and collaboration with Quality Assurance teams to maintain equipment integrity throughout its lifecycle.

Benefit

An Equipment Qualification Engineer likely improves operational efficiency by ensuring all machinery and instruments meet strict regulatory standards, which may reduce downtime and costly compliance issues. This role probably enhances product quality and safety, contributing to overall company reputation and customer trust. Benefits may include career advancement opportunities and exposure to cutting-edge technologies within regulated industries.

Challenge

Equipment Qualification Engineers likely face significant challenges ensuring that complex machinery consistently meets stringent regulatory standards and operational requirements. The role probably demands meticulous attention to detail and problem-solving skills to address unexpected equipment performance issues during qualification phases. Navigating evolving industry guidelines and coordinating cross-functional teams may also present ongoing difficulties in maintaining compliance and project timelines.

Career Advancement

Equipment Qualification Engineers develop expertise in validating machinery and systems within regulated industries, enhancing their technical skills in compliance and quality assurance. Mastery in industry standards such as GMP, FDA, and ISO positions these engineers for leadership roles in quality management and project coordination. Career advancement opportunities include senior engineer roles, quality assurance manager positions, and cross-functional leadership within pharmaceutical, biotech, or manufacturing sectors.

Key Terms

Validation Protocols

Equipment Qualification Engineers develop and execute validation protocols to ensure manufacturing equipment meets regulatory standards and performs reliably. They create detailed Installation Qualification (IQ), Operational Qualification (OQ), and Performance Qualification (PQ) protocols to validate equipment functionality and compliance. Their expertise guarantees that validation processes adhere to Good Manufacturing Practices (GMP) and support quality assurance in production environments.

Installation Qualification (IQ)

An Equipment Qualification Engineer specializing in Installation Qualification (IQ) ensures that all equipment is installed according to predefined specifications, regulatory standards, and manufacturer guidelines. They develop and execute IQ protocols to verify critical parameters such as equipment design, utility requirements, and environmental conditions, minimizing operational risks and ensuring compliance with FDA, EMA, or GMP regulations. Precise documentation and rigorous testing during IQ phases are essential to maintain equipment reliability and facilitate subsequent Operational Qualification (OQ) and Performance Qualification (PQ) processes.

Operational Qualification (OQ)

An Equipment Qualification Engineer specializing in Operational Qualification (OQ) ensures that manufacturing equipment consistently performs according to predefined specifications under actual operating conditions. This role involves developing and executing OQ protocols, analyzing performance data, and collaborating with cross-functional teams to validate equipment reliability and compliance with industry regulations such as cGMP. Expertise in technical documentation, risk assessment, and troubleshooting is essential for maintaining production efficiency and product quality during the OQ phase.

Performance Qualification (PQ)

Performance Qualification (PQ) is a critical responsibility of an Equipment Qualification Engineer, ensuring that equipment consistently operates according to specified parameters under real-world conditions. This process involves detailed protocol development, execution of rigorous testing, and thorough documentation to verify equipment performance meets industry standards and regulatory requirements. Successful PQ completion supports product quality assurance and compliance within pharmaceutical, biotech, and manufacturing sectors.

Good Manufacturing Practice (GMP)

Equipment Qualification Engineers ensure that manufacturing equipment complies with Good Manufacturing Practice (GMP) regulations by conducting Installation Qualification (IQ), Operational Qualification (OQ), and Performance Qualification (PQ) protocols. They develop and execute validation protocols, document test results, and maintain rigorous compliance records to guarantee that equipment consistently produces products meeting quality standards. Expertise in GMP guidelines and industry regulations is essential to support regulatory audits and maintain pharmaceutical manufacturing integrity.

kuljobs.com

kuljobs.com