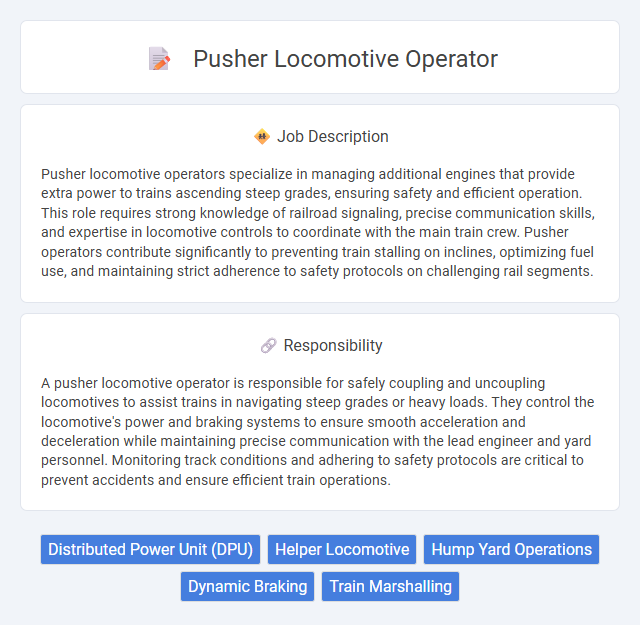

Pusher locomotive operators specialize in managing additional engines that provide extra power to trains ascending steep grades, ensuring safety and efficient operation. This role requires strong knowledge of railroad signaling, precise communication skills, and expertise in locomotive controls to coordinate with the main train crew. Pusher operators contribute significantly to preventing train stalling on inclines, optimizing fuel use, and maintaining strict adherence to safety protocols on challenging rail segments.

Pusher locomotive operator positions may be suitable for individuals who have strong attention to detail, physical endurance, and the ability to remain focused under pressure. Those with good spatial awareness and quick decision-making skills might have a higher probability of thriving in this role due to the demanding operational environment. People prone to high stress or lacking physical stamina could find this job challenging to maintain safely.

Qualification

A Pusher locomotive operator must possess specialized training in heavy machinery operation, with certification in locomotive systems and safety protocols. Experience in coordinating with train crews and understanding rail yard logistics is essential for effective performance. Strong problem-solving skills and the ability to manage high-pressure situations ensure safe and efficient movement of trains on steep gradients.

Responsibility

A pusher locomotive operator is responsible for safely coupling and uncoupling locomotives to assist trains in navigating steep grades or heavy loads. They control the locomotive's power and braking systems to ensure smooth acceleration and deceleration while maintaining precise communication with the lead engineer and yard personnel. Monitoring track conditions and adhering to safety protocols are critical to prevent accidents and ensure efficient train operations.

Benefit

Pusher locomotive operators may experience significant benefits such as competitive wages and opportunities for overtime pay due to the demanding nature of their work. They might also have access to health insurance and retirement plans as part of their employment package. Safety training and job stability in the rail industry could further enhance the overall advantages of this career.

Challenge

The role of a pusher locomotive operator likely involves managing complex rail yard logistics and coordinating multiple rail cars under tight schedules, presenting continuous operational challenges. Handling the locomotive requires precise control and keen situational awareness to ensure safety and efficiency during coupling and pushing maneuvers. Operators may frequently encounter unpredictable track conditions and mechanical issues that demand quick problem-solving and adaptability.

Career Advancement

Pusher locomotive operators play a critical role in assisting trains to ascend steep grades by providing additional power, which requires advanced technical skills and safety knowledge. Career advancement opportunities include transitioning to senior locomotive engineer positions, training roles, or supervisory jobs within rail operations management. Gaining certifications and specialized training in locomotive control systems enhances prospects for higher responsibility and salary growth.

Key Terms

Distributed Power Unit (DPU)

A Pusher Locomotive Operator specializes in controlling Distributed Power Units (DPUs) to enhance train performance on steep grades and long hauls. Managing DPUs requires precise coordination with lead locomotives through radio communication systems to optimize traction and braking power. Expertise in DPU technology ensures efficient fuel usage, improved train handling, and increased safety during operations.

Helper Locomotive

A Pusher locomotive operator specializes in assisting trains by providing additional power to help push heavy loads up steep grades, ensuring safe and efficient rail movement. This Helper Locomotive role requires expertise in synchronizing with the lead engine, monitoring speed, and managing braking systems to prevent derailments during challenging terrain. Operators must have strong knowledge of railway signaling, mechanical systems, and safety protocols to support train operations effectively.

Hump Yard Operations

Pusher locomotive operators play a critical role in hump yard operations by controlling locomotives that push railcars up the hump, facilitating efficient classification and sorting. Expertise in throttle modulation, brake application, and coordination with yard control systems ensures safe and precise handling of railcars during the sorting process. Mastery of hump yard protocols and communication with ground crews optimizes flow and minimizes delays in freight train assembly.

Dynamic Braking

A Pusher locomotive operator expertly manages dynamic braking systems to control train speed on steep gradients, enhancing safety and reducing wear on mechanical brake components. Utilizing dynamic braking, the operator converts kinetic energy into electrical energy, which dissipates as heat, providing precise speed regulation without exhausting conventional brakes. Mastery of this system is crucial for preventing runaway trains and ensuring smooth, efficient rail operations on challenging terrains.

Train Marshalling

Pusher locomotive operators play a critical role in train marshalling by assisting in the movement and positioning of railcars within yards and terminals. They ensure efficient coupling and uncoupling of train sections, optimizing the organization of freight or passenger trains for smooth departure and arrival. Expertise in coordinating with yard controllers and following safety protocols is essential to prevent accidents and maintain operational flow.

kuljobs.com

kuljobs.com