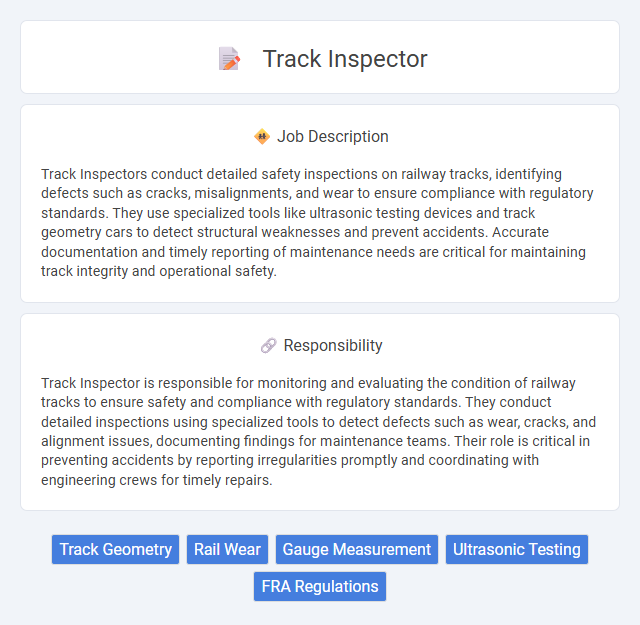

Track Inspectors conduct detailed safety inspections on railway tracks, identifying defects such as cracks, misalignments, and wear to ensure compliance with regulatory standards. They use specialized tools like ultrasonic testing devices and track geometry cars to detect structural weaknesses and prevent accidents. Accurate documentation and timely reporting of maintenance needs are critical for maintaining track integrity and operational safety.

Individuals with strong attention to detail and physical stamina are likely suitable for a Track Inspector role, as the job requires thorough inspection of railway tracks to ensure safety and maintenance standards. Those who can work effectively outdoors in various weather conditions and have the ability to identify potential hazards might find this position fitting. Candidates with limited observational skills or physical endurance may struggle to meet the demands of this occupation.

Qualification

Track Inspector job qualifications typically include a high school diploma or equivalent, with specialized training in railroad safety and track maintenance. Candidates should have a strong understanding of track structure, signaling systems, and relevant Federal Railroad Administration (FRA) regulations. Experience in railway operations, proficiency in using inspection tools and technology, and physical fitness for fieldwork are essential requirements for this role.

Responsibility

Track Inspector is responsible for monitoring and evaluating the condition of railway tracks to ensure safety and compliance with regulatory standards. They conduct detailed inspections using specialized tools to detect defects such as wear, cracks, and alignment issues, documenting findings for maintenance teams. Their role is critical in preventing accidents by reporting irregularities promptly and coordinating with engineering crews for timely repairs.

Benefit

The Track Inspector role likely provides significant benefits such as enhanced job stability due to the critical nature of maintaining railway safety. Candidates may experience job satisfaction from actively preventing accidents and ensuring smooth train operations. Competitive compensation and opportunities for advancement in transportation infrastructure careers could also be expected.

Challenge

The Track Inspector role likely involves significant challenges related to maintaining railway safety and preventing accidents through detailed analysis and regular inspections. Inspectors probably face complex issues such as detecting subtle track defects under various weather conditions and tight schedules. These challenges require keen attention to detail, strong problem-solving skills, and adaptability to ensure continuous safe train operations.

Career Advancement

Track Inspectors play a crucial role in ensuring the safety and maintenance of railway infrastructure, with career advancement opportunities often leading to supervisory or management positions within transportation or engineering sectors. Gaining certifications in railway safety standards and experience in advanced diagnostic technologies significantly enhances prospects for promotion. Continuous professional development through specialized training programs can fast-track a Track Inspector's career progression toward roles such as Track Maintenance Supervisor, Safety Manager, or Railroad Operations Manager.

Key Terms

Track Geometry

Track Inspectors specializing in track geometry ensure the alignment, gauge, and elevation of railway tracks meet safety and operational standards by conducting precise measurements using advanced tools like track geometry cars and laser-based systems. They analyze data related to rail curvature, cant, cross-level, and longitudinal profile to detect defects or deviations that could affect train stability and passenger comfort. Their role is critical in maintaining track integrity, preventing derailments, and maximizing rail network efficiency through routine inspections and timely maintenance recommendations.

Rail Wear

Track Inspectors specialize in monitoring rail wear to ensure railway infrastructure safety and efficiency. They utilize advanced measurement tools such as ultrasonic flaw detectors and rail profile gauges to identify defects like corrugation, head checks, and shelling that can compromise rail integrity. Regular assessment of rail wear patterns enables proactive maintenance, reducing the risk of derailments and extending track lifespan.

Gauge Measurement

Track Inspectors specializing in gauge measurement play a critical role in railroad safety by ensuring the distance between rails complies with strict standards, typically 4 feet 8.5 inches (1,435 mm) for standard gauge tracks. They use precise tools like track gauges and ultrasonic devices to detect deviations that could lead to derailments or equipment damage. Accurate gauge measurement helps maintain optimal train performance and reduces the risk of costly accidents on the rail network.

Ultrasonic Testing

Track Inspectors specializing in Ultrasonic Testing utilize advanced ultrasonic equipment to detect internal rail defects and ensure track integrity. Their expertise in interpreting ultrasonic wave signals enables early identification of cracks, corrosion, and other subsurface anomalies critical for railway safety. Precise flaw detection through ultrasonic methods enhances maintenance planning and reduces the risk of track failures.

FRA Regulations

Track Inspectors ensure compliance with Federal Railroad Administration (FRA) regulations by conducting thorough inspections of railroad tracks, identifying defects, and reporting issues to prevent accidents. They utilize FRA-mandated guidelines and standards for track safety, including measurements of rail gauge, alignment, and track surface conditions. Regular documentation and adherence to FRA safety protocols help maintain infrastructure integrity and enhance overall rail transportation safety.

kuljobs.com

kuljobs.com