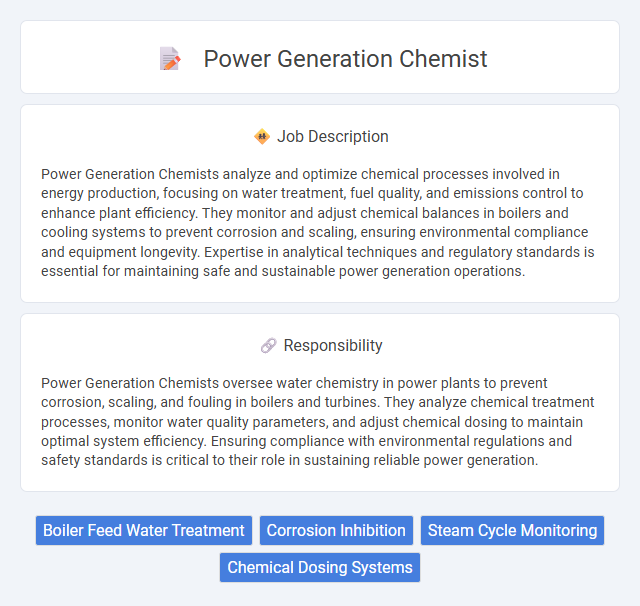

Power Generation Chemists analyze and optimize chemical processes involved in energy production, focusing on water treatment, fuel quality, and emissions control to enhance plant efficiency. They monitor and adjust chemical balances in boilers and cooling systems to prevent corrosion and scaling, ensuring environmental compliance and equipment longevity. Expertise in analytical techniques and regulatory standards is essential for maintaining safe and sustainable power generation operations.

Individuals with strong analytical skills and a passion for chemistry are likely to excel as power generation chemists, given the detailed testing and monitoring required for equipment efficiency and safety. Those comfortable working in industrial settings and following strict safety protocols may find this role particularly suitable. However, candidates who prefer more flexible or less technical work might find the demands of this position challenging.

Qualification

A Power Generation Chemist must hold a degree in Chemistry, Chemical Engineering, or a related field, with specialized knowledge in water treatment, corrosion control, and chemical analysis specific to power plant operations. Proficiency in laboratory techniques, experience with ASTM standards, and familiarity with power generation systems enhance effectiveness in monitoring and optimizing chemical processes. Certifications such as Certified Water Technologist (CWT) or related industry credentials add significant value to the candidate's qualifications.

Responsibility

Power Generation Chemists oversee water chemistry in power plants to prevent corrosion, scaling, and fouling in boilers and turbines. They analyze chemical treatment processes, monitor water quality parameters, and adjust chemical dosing to maintain optimal system efficiency. Ensuring compliance with environmental regulations and safety standards is critical to their role in sustaining reliable power generation.

Benefit

Power Generation Chemists likely contribute to optimizing water and fuel quality, enhancing plant efficiency, and minimizing equipment corrosion, which may lead to cost savings and improved operational reliability. They probably benefit from exposure to advanced technologies and diverse industrial processes, increasing their technical expertise and career growth opportunities. Job stability and competitive compensation are expected benefits given the critical role they play in maintaining sustainable and efficient power production.

Challenge

Power Generation Chemist roles likely involve complex challenges related to maintaining water and steam chemistry to optimize efficiency and prevent corrosion or scaling in power plants. The job probably requires continuous monitoring and adjusting chemical treatments in response to operational variables and environmental factors. Identifying and resolving unexpected chemical imbalances or contamination issues may also present significant difficulties.

Career Advancement

Power Generation Chemists play a crucial role in monitoring and optimizing water chemistry to enhance the efficiency and safety of power plants. Expertise in corrosion control, chemical treatment, and regulatory compliance paves the way for advancement to senior technical specialist or plant operations manager roles. Gaining certifications such as Certified Water Technologist (CWT) and developing skills in data analysis and process optimization further accelerate career growth within the energy sector.

Key Terms

Boiler Feed Water Treatment

Power Generation Chemists specializing in Boiler Feed Water Treatment play a critical role in maintaining the chemical balance and purity of water used in boiler systems, preventing scale formation, corrosion, and fouling that can impair turbine efficiency. They analyze water samples for parameters like hardness, pH, silica, and dissolved oxygen, implementing tailored chemical dosing programs to ensure optimal boiler performance and longevity. Expertise in treatment chemicals such as phosphates, oxygen scavengers, and anti-foaming agents is essential for sustaining safe and cost-effective power plant operations.

Corrosion Inhibition

Power generation chemists specializing in corrosion inhibition develop and optimize chemical treatments to prevent metal degradation in boilers, turbines, and cooling systems of power plants. They analyze water chemistry parameters such as pH, dissolved oxygen, and conductivity to tailor inhibitor formulations that enhance equipment lifespan and operational efficiency. Their expertise in corrosion mechanisms and material compatibility is crucial for minimizing maintenance costs and ensuring reliable energy production.

Steam Cycle Monitoring

A Power Generation Chemist specializing in Steam Cycle Monitoring ensures optimal water chemistry to prevent corrosion, scaling, and deposition in boilers, turbines, and condensers. They conduct regular sampling and analysis of steam, feedwater, and condensate to maintain strict compliance with industry standards such as ASME and ASTM. Expertise in chemical dosing, trending of water quality parameters, and troubleshooting cycle chemistry issues is crucial for maximizing thermal efficiency and extending equipment lifespan.

Chemical Dosing Systems

Power Generation Chemists specializing in Chemical Dosing Systems are responsible for optimizing the injection of precise chemical doses to control corrosion, scaling, and microbial growth in power plant water circuits. Expertise in chemical compatibility and real-time monitoring technology ensures efficient operation of boilers, cooling towers, and condensate lines while maintaining environmental compliance. Their role directly impacts boiler longevity, energy efficiency, and regulatory adherence in thermal and nuclear power generation facilities.

kuljobs.com

kuljobs.com