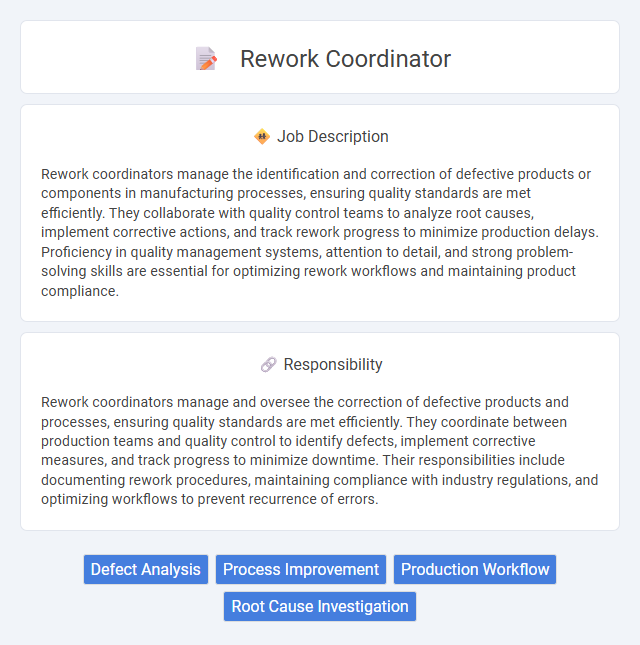

Rework coordinators manage the identification and correction of defective products or components in manufacturing processes, ensuring quality standards are met efficiently. They collaborate with quality control teams to analyze root causes, implement corrective actions, and track rework progress to minimize production delays. Proficiency in quality management systems, attention to detail, and strong problem-solving skills are essential for optimizing rework workflows and maintaining product compliance.

Individuals with strong attention to detail and problem-solving skills will likely find the rework coordinator role suitable. Those who thrive in organized, fast-paced environments where managing workflows and coordinating teams is essential may have a higher probability of success. However, people who prefer less structured tasks or struggle with multitasking might find this position challenging.

Qualification

Rework coordinators typically require a blend of technical expertise and project management skills, often holding qualifications such as a degree in engineering, manufacturing, or quality assurance. Proficiency in data analysis, process improvement methodologies like Six Sigma, and experience with supply chain coordination enhances their effectiveness. Strong communication skills and attention to detail are essential for managing schedules, coordinating teams, and ensuring compliance with quality standards.

Responsibility

Rework coordinators manage and oversee the correction of defective products and processes, ensuring quality standards are met efficiently. They coordinate between production teams and quality control to identify defects, implement corrective measures, and track progress to minimize downtime. Their responsibilities include documenting rework procedures, maintaining compliance with industry regulations, and optimizing workflows to prevent recurrence of errors.

Benefit

Rework coordinators likely enhance manufacturing efficiency by systematically identifying and managing product defects, which could reduce waste and lower production costs. Their role probably supports improved quality control, leading to higher customer satisfaction and fewer returns. Organizations may benefit from streamlined workflows and increased profitability through effective rework coordination.

Challenge

A Rework Coordinator likely faces the challenge of efficiently managing workflow disruptions caused by product defects or process deviations. They probably need to balance tight production schedules with quality standards, ensuring minimal downtime and resource wastage. Effective communication and problem-solving skills are expected to be crucial in resolving issues quickly and maintaining overall operational efficiency.

Career Advancement

A Rework Coordinator plays a critical role in overseeing the repair and reconditioning of products to ensure quality standards are met efficiently. Expertise in quality control, workflow optimization, and cross-departmental collaboration opens pathways to senior management roles such as Quality Assurance Manager or Production Supervisor. Mastery of data analysis and process improvement tools accelerates career advancement opportunities within manufacturing and supply chain sectors.

Key Terms

Defect Analysis

Rework coordinators oversee defect analysis by systematically identifying and categorizing product flaws during the manufacturing process to ensure quality standards are met. They utilize root cause analysis techniques and collaborate with quality control teams to determine corrective actions that minimize rework costs and improve production efficiency. Accurate defect tracking and reporting enable data-driven decisions that enhance overall product reliability and reduce downtime.

Process Improvement

Rework coordinators drive process improvement by identifying inefficiencies and developing corrective action plans to reduce defects and rework cycles. They analyze production data and implement quality control measures that enhance workflow efficiency and product consistency. Their role ensures continuous improvement within manufacturing processes, leading to cost savings and higher customer satisfaction.

Production Workflow

A Rework Coordinator manages and streamlines production workflow by identifying, assessing, and correcting product defects to ensure quality standards are met efficiently. They coordinate with production teams to implement corrective actions, track rework progress, and minimize downtime, optimizing the overall manufacturing process. Effective rework coordination improves throughput, reduces waste, and supports continuous improvement initiatives within the production facility.

Root Cause Investigation

Rework coordinators specialize in root cause investigation by systematically analyzing defects and process failures to identify underlying issues. They utilize tools such as fishbone diagrams, Pareto analysis, and 5 Whys to pinpoint the exact origin of rework needs. This focused approach ensures effective corrective actions are implemented, reducing recurrence and improving overall production quality.

kuljobs.com

kuljobs.com