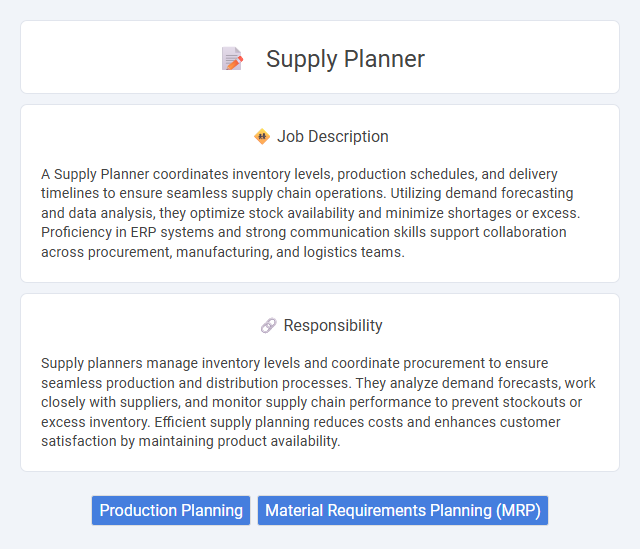

A Supply Planner coordinates inventory levels, production schedules, and delivery timelines to ensure seamless supply chain operations. Utilizing demand forecasting and data analysis, they optimize stock availability and minimize shortages or excess. Proficiency in ERP systems and strong communication skills support collaboration across procurement, manufacturing, and logistics teams.

Individuals with strong analytical skills and attention to detail are likely suitable for a supply planner role, as the job demands precise inventory management and demand forecasting. Those who thrive in structured environments and can effectively coordinate among multiple departments may find this position aligns well with their abilities. People who struggle with multitasking or handling pressure might face challenges in meeting the dynamic requirements of supply planning.

Qualification

A Supply Planner typically requires a bachelor's degree in supply chain management, logistics, or business administration, coupled with proficiency in demand forecasting and inventory management software like SAP or Oracle. Strong analytical skills, attention to detail, and the ability to interpret complex data sets are essential for optimizing supply chain processes. Experience in ERP systems, excellent communication skills, and knowledge of lean manufacturing principles enhance effectiveness in coordinating production schedules and supplier relationships.

Responsibility

Supply planners manage inventory levels and coordinate procurement to ensure seamless production and distribution processes. They analyze demand forecasts, work closely with suppliers, and monitor supply chain performance to prevent stockouts or excess inventory. Efficient supply planning reduces costs and enhances customer satisfaction by maintaining product availability.

Benefit

A Supply Planner role likely offers significant benefits such as improved career growth opportunities in logistics and operations management. It probably enhances skills in demand forecasting, inventory control, and supplier coordination, which are highly valued in various industries. The position may also provide job stability and competitive compensation due to its critical influence on supply chain efficiency.

Challenge

Supply planner roles likely involve tackling the challenge of balancing inventory levels to meet fluctuating customer demand without overstocking. Forecast accuracy may pose ongoing difficulties due to variable market conditions and supply chain disruptions. Managing these uncertainties probably requires strong analytical skills and proactive communication with suppliers and internal teams.

Career Advancement

A supply planner plays a crucial role in managing inventory levels, coordinating production schedules, and optimizing supply chain efficiency to meet demand forecasts. Advancing in this career often leads to positions such as senior supply planner, supply chain manager, or operations director, where strategic decision-making and leadership skills become essential. Mastery of advanced analytics, demand forecasting software, and cross-functional collaboration significantly enhances opportunities for career growth in the supply planning field.

Key Terms

Production Planning

A Supply Planner specializing in Production Planning coordinates material requirements and production schedules to optimize manufacturing efficiency and meet delivery targets. They analyze demand forecasts, inventory levels, and production capacity to develop actionable plans that minimize lead times and reduce costs. Proficiency in ERP systems and strong communication skills are essential for aligning cross-functional teams and ensuring seamless supply chain operations.

Material Requirements Planning (MRP)

Supply planners utilize Material Requirements Planning (MRP) systems to accurately forecast demand, schedule production, and manage inventory levels. MRP helps optimize the procurement of raw materials and components, reducing stockouts and minimizing excess inventory costs. Proficiency in MRP software enhances a supply planner's ability to align supply with demand, ensuring timely delivery and operational efficiency.

kuljobs.com

kuljobs.com