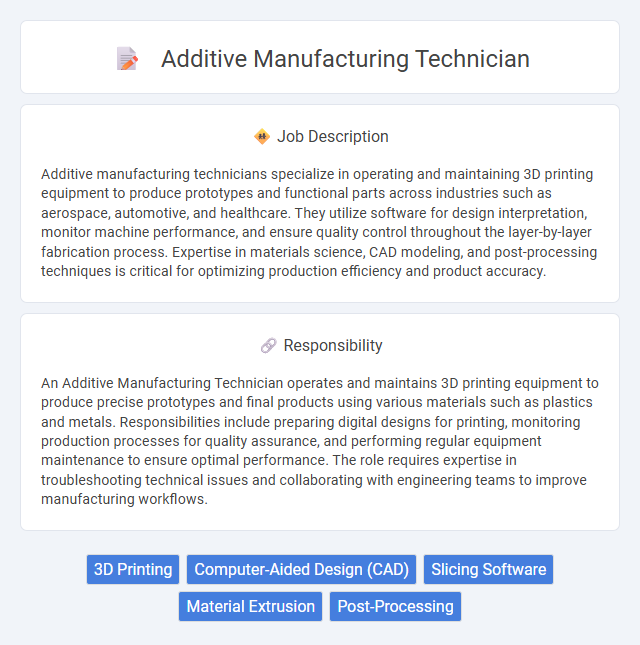

Additive manufacturing technicians specialize in operating and maintaining 3D printing equipment to produce prototypes and functional parts across industries such as aerospace, automotive, and healthcare. They utilize software for design interpretation, monitor machine performance, and ensure quality control throughout the layer-by-layer fabrication process. Expertise in materials science, CAD modeling, and post-processing techniques is critical for optimizing production efficiency and product accuracy.

Individuals with strong attention to detail and a passion for technology may be well-suited for a career as an additive manufacturing technician. Those who enjoy hands-on work and problem-solving could likely thrive in this field, given the intricate nature of 3D printing processes. People who prefer repetitive or less technical tasks might find this role less compatible with their skills and interests.

Qualification

An Additive Manufacturing Technician typically requires a background in engineering or manufacturing technology, with certifications in 3D printing technologies such as FDM, SLS, or SLA. Proficiency in CAD software and materials science is essential for optimizing print quality and production efficiency. Strong analytical skills and experience in troubleshooting additive manufacturing equipment enhance job performance and ensure adherence to industry standards.

Responsibility

An Additive Manufacturing Technician operates and maintains 3D printing equipment to produce precise prototypes and final products using various materials such as plastics and metals. Responsibilities include preparing digital designs for printing, monitoring production processes for quality assurance, and performing regular equipment maintenance to ensure optimal performance. The role requires expertise in troubleshooting technical issues and collaborating with engineering teams to improve manufacturing workflows.

Benefit

Additive manufacturing technician roles likely offer benefits such as hands-on experience with cutting-edge 3D printing technologies, enhancing technical skills valuable in industries like aerospace and healthcare. There is a probability of career growth due to increasing adoption of additive manufacturing in various sectors. Competitive salaries and opportunities for continuous learning may also be common benefits in this field.

Challenge

Additive manufacturing technicians are likely to encounter challenges related to maintaining precise control over complex 3D printing processes and troubleshooting equipment malfunctions that can impact product quality. They may also face the difficulty of staying updated with rapidly evolving technologies and materials used in additive manufacturing. Problem-solving skills and adaptability are probably essential to overcome these technical and operational obstacles effectively.

Career Advancement

Additive manufacturing technicians specialize in operating and maintaining 3D printing equipment, playing a critical role in prototyping and production across industries like aerospace and automotive. Mastery of advanced software and materials science can lead to career advancement into roles such as additive manufacturing engineer or production manager. Continuous skill development in new printing technologies and certifications enhances prospects for leadership positions within manufacturing and design innovation teams.

Key Terms

3D Printing

An Additive Manufacturing Technician specializes in operating and maintaining 3D printing equipment to produce high-precision prototypes and components using materials such as thermoplastics, resins, and metals. Expertise in software for 3D modeling, slicing, and printer calibration ensures optimal print quality and adherence to design specifications. Strong knowledge of post-processing techniques and quality control processes is essential for delivering durable, functional parts in industries like aerospace, automotive, and healthcare.

Computer-Aided Design (CAD)

Additive manufacturing technicians specialize in using Computer-Aided Design (CAD) software to create precise 3D models for printing complex components. Proficiency in CAD platforms such as SolidWorks, AutoCAD, or Fusion 360 enables technicians to optimize designs for material efficiency and structural integrity in additive manufacturing processes. This expertise directly impacts production speed, accuracy, and innovation in industries like aerospace, automotive, and medical device manufacturing.

Slicing Software

Additive manufacturing technicians specialize in preparing 3D models for printing by utilizing slicing software to convert digital designs into precise, printable layers. Mastery of slicing software such as Ultimaker Cura, PrusaSlicer, or Simplify3D enables the technician to optimize print speed, material usage, and final product quality. Expertise in adjusting parameters like layer height, infill density, and support structures directly impacts the efficiency and accuracy of the additive manufacturing process.

Material Extrusion

Additive manufacturing technicians specializing in material extrusion operate advanced 3D printers that precisely deposit thermoplastic filaments to create complex parts layer by layer. They monitor printer settings, perform maintenance, and ensure quality control, optimizing parameters such as temperature, feed rate, and layer thickness for optimal mechanical properties. Expertise in materials like PLA, ABS, and PETG is essential to troubleshoot defects and enhance tensile strength and surface finish in the final products.

Post-Processing

Additive manufacturing technicians specializing in post-processing perform critical tasks such as support removal, surface finishing, and heat treatment to ensure high-quality final products. Proficiency in techniques like sanding, polishing, and chemical smoothing enhances part durability and aesthetic appeal. Expertise in operating post-processing equipment and adherence to quality control standards drives consistent production efficiency and component reliability.

kuljobs.com

kuljobs.com