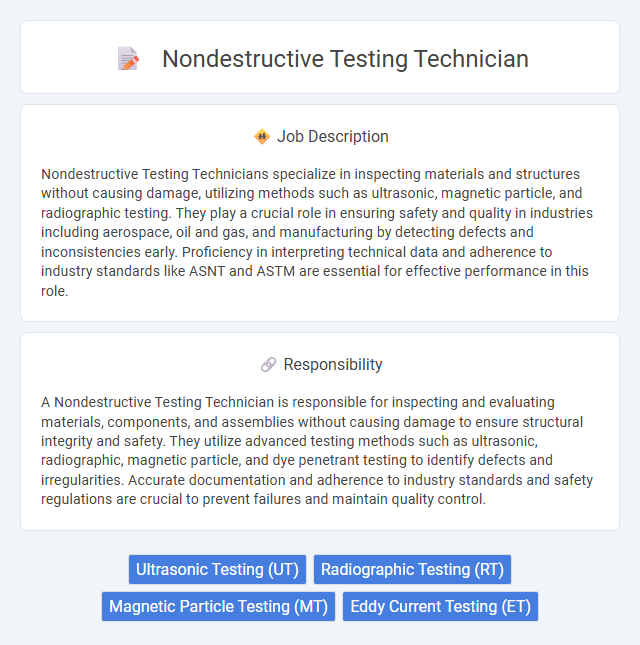

Nondestructive Testing Technicians specialize in inspecting materials and structures without causing damage, utilizing methods such as ultrasonic, magnetic particle, and radiographic testing. They play a crucial role in ensuring safety and quality in industries including aerospace, oil and gas, and manufacturing by detecting defects and inconsistencies early. Proficiency in interpreting technical data and adherence to industry standards like ASNT and ASTM are essential for effective performance in this role.

Individuals with strong attention to detail and a steady hand are likely well-suited for a Nondestructive Testing Technician role due to the precision required in inspecting materials and structures. Candidates with a background in engineering or technical fields may have a higher probability of success, while those who struggle with complex equipment or working in confined spaces might find the job challenging. Physical stamina and the ability to work in various environments could also influence suitability for this occupation.

Qualification

A Nondestructive Testing (NDT) Technician must possess certifications such as ASNT Level I or II in methods like ultrasonic testing, radiographic testing, magnetic particle testing, or dye penetrant testing. Proficiency in interpreting technical drawings and adherence to safety standards like ASTM and ISO is essential for accurate defect detection. Strong analytical skills and experience with industry-specific equipment enhance reliability in evaluating material integrity without causing damage.

Responsibility

A Nondestructive Testing Technician is responsible for inspecting and evaluating materials, components, and assemblies without causing damage to ensure structural integrity and safety. They utilize advanced testing methods such as ultrasonic, radiographic, magnetic particle, and dye penetrant testing to identify defects and irregularities. Accurate documentation and adherence to industry standards and safety regulations are crucial to prevent failures and maintain quality control.

Benefit

A Nondestructive Testing Technician job likely offers strong benefits such as competitive salaries and comprehensive health insurance packages, reflecting the specialized skills required. Opportunities for career advancement and ongoing training programs may increase job stability and professional growth potential. Access to retirement plans and paid time off often accompanies positions in this field, enhancing overall job satisfaction.

Challenge

Nondestructive Testing Technicians likely encounter complex challenges requiring precise evaluation of materials and structures without causing damage. The job probably demands continuous learning to stay updated with evolving testing technologies and industry standards. Problem-solving skills are commonly essential for interpreting test results and ensuring safety and quality compliance in various sectors.

Career Advancement

Nondestructive Testing Technicians gain critical skills in methods such as ultrasonic, radiographic, and magnetic particle testing, opening pathways for specialization in advanced inspection techniques or quality assurance roles. Progression opportunities often lead to supervisory positions, certification as Level II or III inspectors, or transition into engineering and safety management fields. Continuous professional development and obtaining industry-recognized certifications like ASNT or AWS significantly enhance career advancement prospects within the NDT sector.

Key Terms

Ultrasonic Testing (UT)

Nondestructive Testing Technicians specializing in Ultrasonic Testing (UT) utilize high-frequency sound waves to detect internal flaws in materials without causing damage, ensuring structural integrity and safety. Proficiency with UT equipment such as pulser/receiver units and ultrasonic probes is essential for accurately interpreting test results. Strong knowledge of material properties and standards like ASTM E164 guides technicians in performing precise inspections across industries like aerospace, oil and gas, and manufacturing.

Radiographic Testing (RT)

Radiographic Testing (RT) is a key skill for a Nondestructive Testing Technician, involving the use of X-rays or gamma rays to inspect welds, castings, and structural components for internal defects without causing damage. Proficiency in interpreting radiographic images and adhering to safety standards is essential to ensure accurate quality assessments and maintain compliance with industry regulations. Expertise in RT enhances a technician's ability to detect flaws such as cracks, voids, and inclusions, contributing to the overall integrity and safety of critical infrastructure.

Magnetic Particle Testing (MT)

Nondestructive Testing Technicians specializing in Magnetic Particle Testing (MT) utilize magnetic fields to detect surface and near-surface discontinuities in ferromagnetic materials, ensuring structural integrity without causing damage. MT is essential in industries such as aerospace, automotive, and construction for identifying cracks, seams, and other defects with high accuracy. Proficiency in interpreting magnetic particle indications and adhering to safety standards is critical for maintaining quality control and preventing failure in critical components.

Eddy Current Testing (ET)

Nondestructive Testing Technicians specializing in Eddy Current Testing (ET) use electromagnetic induction to detect surface and subsurface flaws in conductive materials without damaging the test object. Expertise in interpreting signal variations allows technicians to identify cracks, corrosion, and thickness changes critical for maintaining safety standards in aerospace, automotive, and power generation industries. Proficiency with ET equipment, calibration procedures, and compliance with ASTM E Eddy Current standards ensures accurate and reliable inspection results.

kuljobs.com

kuljobs.com