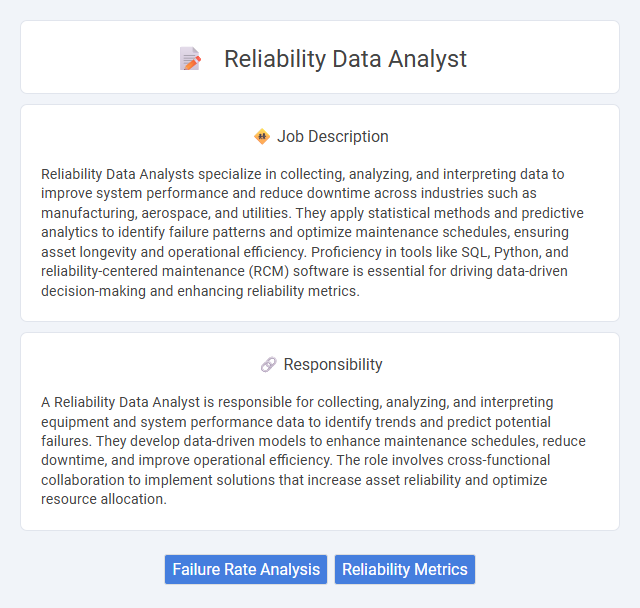

Reliability Data Analysts specialize in collecting, analyzing, and interpreting data to improve system performance and reduce downtime across industries such as manufacturing, aerospace, and utilities. They apply statistical methods and predictive analytics to identify failure patterns and optimize maintenance schedules, ensuring asset longevity and operational efficiency. Proficiency in tools like SQL, Python, and reliability-centered maintenance (RCM) software is essential for driving data-driven decision-making and enhancing reliability metrics.

Individuals with strong analytical skills and a detail-oriented mindset are likely well-suited for a Reliability Data Analyst position. Candidates who enjoy working with complex data sets to identify patterns and improve system performance may find this role rewarding. Those indifferent to repetitive data analysis or lacking patience for meticulous evaluation might face challenges in this career.

Qualification

A Reliability Data Analyst typically requires a strong background in data analysis, statistics, and engineering principles. Proficiency in tools such as SQL, Python, R, and reliability software like Weibull++ or ReliaSoft is essential for analyzing failure rates and maintenance data. A degree in engineering, statistics, or a related field, combined with experience in reliability engineering and data visualization, enhances qualification for this role.

Responsibility

A Reliability Data Analyst is responsible for collecting, analyzing, and interpreting equipment and system performance data to identify trends and predict potential failures. They develop data-driven models to enhance maintenance schedules, reduce downtime, and improve operational efficiency. The role involves cross-functional collaboration to implement solutions that increase asset reliability and optimize resource allocation.

Benefit

A Reliability Data Analyst likely enhances organizational efficiency by identifying patterns in equipment performance and predicting potential failures, which may reduce downtime and maintenance costs. This role probably supports data-driven decision-making, leading to improved asset management and operational reliability. Companies employing this position might experience increased productivity and extended equipment lifespan as a result.

Challenge

The Reliability Data Analyst role likely involves the challenge of interpreting complex datasets to predict equipment failures and improve system dependability. Analysts may need to navigate incomplete or inconsistent data, requiring sophisticated statistical techniques and domain expertise. The position probably demands continuous adaptation to emerging technologies and evolving industry standards to maintain accuracy and relevance.

Career Advancement

Reliability Data Analysts play a critical role in enhancing equipment performance and reducing downtime by analyzing complex datasets related to maintenance and failure rates. Mastery of statistical software and predictive analytics tools increases opportunities for advancement into senior analyst, reliability engineer, or data science managerial positions. Expertise in reliability-centered maintenance and root cause analysis positions professionals for leadership roles in asset management and operational reliability strategy.

Key Terms

Failure Rate Analysis

A Reliability Data Analyst specializing in Failure Rate Analysis evaluates equipment performance metrics to identify patterns of failure and predict potential breakdowns. They utilize statistical tools and reliability engineering principles to calculate failure rates, improve maintenance schedules, and enhance asset life cycles. Proficient in data extraction, trend analysis, and risk assessment, they contribute to reducing downtime and optimizing operational efficiency.

Reliability Metrics

A Reliability Data Analyst specializes in collecting and analyzing reliability metrics such as Mean Time Between Failures (MTBF), Failure Rate, and Availability to assess system performance and predict maintenance needs. Expertise in data visualization tools, statistical analysis, and reliability-centered maintenance (RCM) methodologies enables accurate identification of patterns and root causes of equipment failures. Proficiency in software like R, Python, or specialized reliability tools enhances the ability to generate actionable insights that improve asset reliability and reduce downtime.

kuljobs.com

kuljobs.com