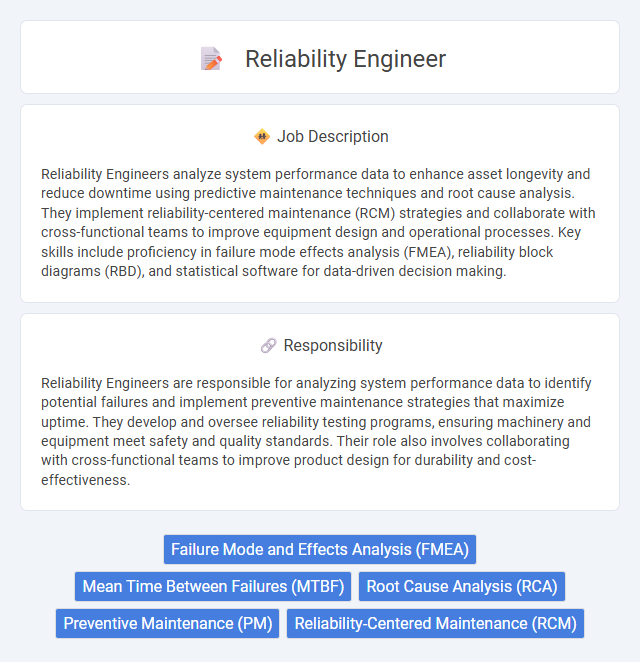

Reliability Engineers analyze system performance data to enhance asset longevity and reduce downtime using predictive maintenance techniques and root cause analysis. They implement reliability-centered maintenance (RCM) strategies and collaborate with cross-functional teams to improve equipment design and operational processes. Key skills include proficiency in failure mode effects analysis (FMEA), reliability block diagrams (RBD), and statistical software for data-driven decision making.

Individuals with strong analytical skills, attention to detail, and a methodical approach may likely find themselves well-suited for a Reliability Engineer role. Those who enjoy problem-solving, working with complex systems, and continuously improving processes could probably adapt successfully to this position. A preference for teamwork and effective communication might increase the probability of thriving in this dynamic, data-driven environment.

Qualification

Reliability Engineers typically require a bachelor's degree in engineering disciplines such as mechanical, electrical, or industrial engineering, often complemented by certifications like Certified Reliability Engineer (CRE) from ASQ. Expertise in failure mode effects analysis (FMEA), root cause analysis (RCA), and reliability-centered maintenance (RCM) is essential to optimize system performance and minimize downtime. Proficiency in statistical tools and software such as Weibull analysis and reliability block diagrams enhances predictive maintenance and asset integrity management.

Responsibility

Reliability Engineers are responsible for analyzing system performance data to identify potential failures and implement preventive maintenance strategies that maximize uptime. They develop and oversee reliability testing programs, ensuring machinery and equipment meet safety and quality standards. Their role also involves collaborating with cross-functional teams to improve product design for durability and cost-effectiveness.

Benefit

A Reliability Engineer likely enhances equipment uptime and reduces maintenance costs, resulting in significant operational savings. This role probably improves product quality and customer satisfaction by ensuring consistent system performance. Companies may benefit from increased safety standards and compliance adherence, supporting long-term business sustainability.

Challenge

Reliability Engineer roles likely present ongoing challenges in predicting and preventing system failures to ensure continuous operation. They probably face complex problem-solving situations requiring deep technical expertise and data analysis skills. Managing reliability within budget constraints and evolving technology environments seems to be a common difficulty in such positions.

Career Advancement

Reliability Engineers play a critical role in improving system performance and reducing downtime, leveraging data analysis and predictive maintenance techniques. Career advancement often leads to senior engineering positions, management roles such as Reliability Manager, or specialized fields like Risk Assessment and Asset Management. Continuous skill development in IoT technologies, machine learning, and reliability-centered maintenance enhances job prospects and leadership opportunities.

Key Terms

Failure Mode and Effects Analysis (FMEA)

Reliability Engineers specialize in Failure Mode and Effects Analysis (FMEA) to systematically identify potential failure points within products and processes, assessing their impact on overall system performance. By prioritizing failure modes based on severity, occurrence, and detection, they develop mitigation strategies that enhance reliability and reduce downtime. Expertise in FMEA enables the early identification of risks, improving product quality and customer satisfaction through proactive failure prevention.

Mean Time Between Failures (MTBF)

Reliability Engineers specialize in analyzing and improving Mean Time Between Failures (MTBF) to enhance system performance and minimize downtime. By conducting failure mode effects analysis (FMEA) and implementing maintenance strategies, they increase the operational lifespan of components. Accurate MTBF calculations guide preventive maintenance schedules and optimize reliability in manufacturing, aerospace, and electronics industries.

Root Cause Analysis (RCA)

Root Cause Analysis (RCA) is a critical skill for a Reliability Engineer, enabling the identification and resolution of underlying issues affecting equipment and system performance. Utilizing data-driven techniques such as Failure Mode and Effects Analysis (FMEA) and Pareto charts, RCA helps improve operational uptime and reduce maintenance costs. Effective implementation of RCA fosters continuous improvement in asset reliability and supports proactive risk management strategies.

Preventive Maintenance (PM)

Reliability Engineers specialize in designing and implementing Preventive Maintenance (PM) programs that enhance equipment longevity and operational efficiency. They analyze failure data to predict potential breakdowns, optimize maintenance schedules, and reduce downtime. Expertise in PM software tools and root cause analysis enables them to drive continuous improvements in asset reliability and cost-effectiveness.

Reliability-Centered Maintenance (RCM)

Reliability Engineers specializing in Reliability-Centered Maintenance (RCM) develop and implement maintenance strategies that maximize equipment availability while minimizing operational costs and risks. They analyze system functions, failure modes, and consequences to prioritize maintenance tasks that ensure optimal asset performance. Their expertise drives continuous improvement in maintenance planning, enhancing overall reliability and safety across industrial operations.

kuljobs.com

kuljobs.com