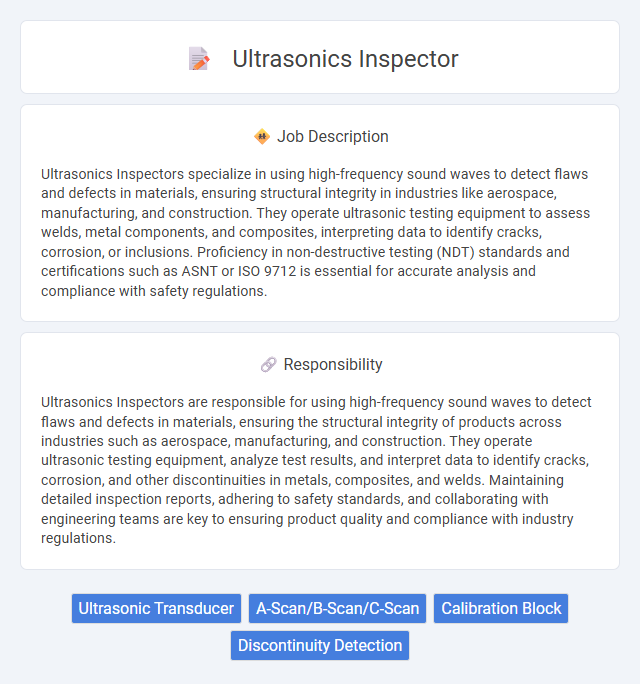

Ultrasonics Inspectors specialize in using high-frequency sound waves to detect flaws and defects in materials, ensuring structural integrity in industries like aerospace, manufacturing, and construction. They operate ultrasonic testing equipment to assess welds, metal components, and composites, interpreting data to identify cracks, corrosion, or inclusions. Proficiency in non-destructive testing (NDT) standards and certifications such as ASNT or ISO 9712 is essential for accurate analysis and compliance with safety regulations.

Ultrasonics Inspectors are likely to be well-suited for individuals with strong attention to detail, excellent hand-eye coordination, and a good grasp of technical concepts. People with a calm demeanor and the ability to work in confined or noisy environments may find this job more appropriate. Those prone to stress or with poor eyesight could potentially face challenges in performing ultrasonic inspections efficiently.

Qualification

Ultrasonics Inspectors must possess certifications such as ASNT Level II or III to effectively perform non-destructive testing using ultrasonic equipment. Proficiency in reading blueprints, interpreting technical drawings, and understanding material specifications is essential for accurate flaw detection. Strong knowledge of ultrasonic testing principles, coupled with hands-on experience in various industries like aerospace or manufacturing, ensures reliable inspection outcomes.

Responsibility

Ultrasonics Inspectors are responsible for using high-frequency sound waves to detect flaws and defects in materials, ensuring the structural integrity of products across industries such as aerospace, manufacturing, and construction. They operate ultrasonic testing equipment, analyze test results, and interpret data to identify cracks, corrosion, and other discontinuities in metals, composites, and welds. Maintaining detailed inspection reports, adhering to safety standards, and collaborating with engineering teams are key to ensuring product quality and compliance with industry regulations.

Benefit

Ultrasonics inspectors likely benefit from high demand in industries such as aerospace, manufacturing, and construction, leading to stable employment opportunities. They probably experience competitive salaries reflecting the technical expertise required for accurate flaw detection and material evaluation. Safety improvements and equipment longevity resulting from their work may also contribute to job satisfaction and professional growth prospects.

Challenge

The Ultrasonics Inspector role likely presents the challenge of accurately detecting flaws in complex materials using advanced ultrasonic technology. Mastery of interpreting ultrasonic signals and adapting to varying inspection environments could be critical for success. The probability of encountering unexpected material inconsistencies requires a vigilant and detail-oriented approach to ensure safety and quality standards.

Career Advancement

Ultrasonics Inspectors play a critical role in non-destructive testing, using ultrasonic technology to detect flaws in materials and ensure structural integrity. Career advancement opportunities include progressing to senior inspection roles, quality control management, or specializing in advanced ultrasonic testing techniques and certification levels. Gaining certifications such as ASNT Level II or III significantly enhances prospects for leadership positions and higher salary brackets within industries like aerospace, manufacturing, and oil & gas.

Key Terms

Ultrasonic Transducer

An Ultrasonics Inspector specializes in using advanced ultrasonic transducers to detect internal flaws and inconsistencies in materials without causing damage. The ultrasonic transducer emits high-frequency sound waves that penetrate the test object, reflecting back data that the inspector analyzes to assess structural integrity. Mastery of transducer calibration, coupling techniques, and signal interpretation is essential for accurate defect identification and quality assurance in manufacturing and construction industries.

A-Scan/B-Scan/C-Scan

Ultrasonics Inspectors specialize in non-destructive testing using A-Scan, B-Scan, and C-Scan techniques to detect internal flaws and material thickness in various industrial components. A-Scan provides one-dimensional time-based echo information, ideal for depth and thickness measurements, while B-Scan offers a two-dimensional cross-sectional image to visualize defects within the material structure. C-Scan generates a detailed map view of the scanned area, enabling precise defect localization and comprehensive assessment of welds, composites, and metal parts.

Calibration Block

Ultrasonics inspectors utilize calibration blocks to ensure accurate measurement and flaw detection during non-destructive testing (NDT) of materials. These calibration blocks, typically made from reference materials with known properties, are essential for setting ultrasonic equipment to precise frequencies and velocities. Proper use of calibration blocks enhances the reliability of inspections by validating equipment performance and standardizing testing procedures.

Discontinuity Detection

Ultrasonics Inspectors specialize in discontinuity detection by using high-frequency sound waves to identify flaws such as cracks, voids, or inclusions in materials. They operate ultrasonic testing equipment, analyze signal responses, and interpret data to ensure structural integrity and compliance with safety standards. Mastery in flaw sizing, location determination, and documentation of inspection results is critical for preventing material failure.

kuljobs.com

kuljobs.com