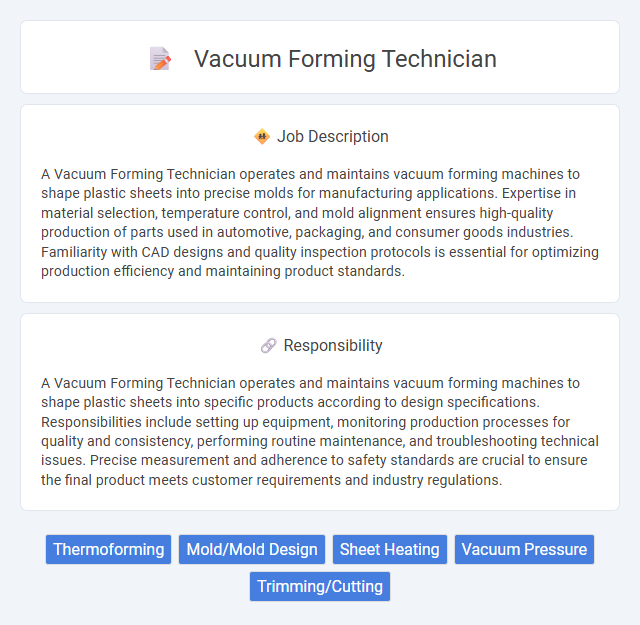

A Vacuum Forming Technician operates and maintains vacuum forming machines to shape plastic sheets into precise molds for manufacturing applications. Expertise in material selection, temperature control, and mold alignment ensures high-quality production of parts used in automotive, packaging, and consumer goods industries. Familiarity with CAD designs and quality inspection protocols is essential for optimizing production efficiency and maintaining product standards.

Individuals with strong manual dexterity and good hand-eye coordination are more likely to excel as vacuum forming technicians. Those who tolerate repetitive tasks and maintain focus in fast-paced manufacturing environments will probably find this role suitable. Candidates with physical stamina and attention to detail may have a higher probability of success in this job.

Qualification

Vacuum forming technicians require proficiency in operating thermoforming machinery and interpreting technical blueprints to produce precise plastic components. Essential qualifications include a high school diploma or equivalent, supplemented by vocational training or certifications in plastics technology or manufacturing processes. Strong mechanical aptitude, attention to detail, and familiarity with safety protocols are critical for ensuring efficient production and maintaining quality standards.

Responsibility

A Vacuum Forming Technician operates and maintains vacuum forming machines to shape plastic sheets into specific products according to design specifications. Responsibilities include setting up equipment, monitoring production processes for quality and consistency, performing routine maintenance, and troubleshooting technical issues. Precise measurement and adherence to safety standards are crucial to ensure the final product meets customer requirements and industry regulations.

Benefit

A Vacuum Forming Technician job likely offers the benefit of developing specialized skills in thermoforming processes, which may lead to enhanced career opportunities in manufacturing and product design industries. The position probably provides hands-on experience with advanced machinery, increasing technical proficiency and employability. It may also include stable work hours and potential for growth within industrial or prototyping environments.

Challenge

Vacuum forming technicians may face challenges related to precise temperature control and material handling to ensure high-quality product outcomes. Troubleshooting equipment malfunctions and adapting to varying material properties often require considerable skill and attention to detail. The probability of encountering tight production deadlines can further increase the complexity of the role.

Career Advancement

Vacuum forming technicians gain valuable hands-on experience with thermoforming plastics, developing skills in mold design, machine setup, and quality control that open pathways to senior technical roles. Mastery of CAD software and materials science within this role accelerates promotion opportunities to production supervisor or process engineer positions. Career advancement often involves specialization in precision forming techniques or transitioning into manufacturing management, driving both technical expertise and leadership growth.

Key Terms

Thermoforming

A Vacuum Forming Technician specializes in thermoforming processes, using heat and vacuum to mold plastic sheets into specific shapes for packaging, automotive parts, and product displays. Expertise in operating and maintaining vacuum forming machines ensures precise temperature control and material handling for high-quality finished goods. Knowledge of various thermoplastic materials and quality assurance techniques is critical to optimize production efficiency and reduce waste.

Mold/Mold Design

Vacuum forming technicians specialize in creating precise molds that shape plastic sheets through controlled heat and pressure, ensuring accurate replication of design specifications. Expertise in mold design, including material selection and cavity geometry, is critical to optimize production efficiency and achieve high-quality surface finishes. Mastery of CAD software and understanding of mold release agents enhance the technician's ability to consistently produce durable, defect-free vacuum-formed parts.

Sheet Heating

A Vacuum Forming Technician specializes in heating plastic sheets to precise temperatures to ensure optimal pliability for molding. Mastery in controlling heating elements, including infrared and convection systems, allows for consistent temperature distribution crucial for preventing material defects. Expertise in monitoring sheet temperature profiles directly impacts product quality and efficiency in the vacuum forming production process.

Vacuum Pressure

A Vacuum forming technician specializes in shaping plastic materials by applying precise vacuum pressure to mold sheets over a form. Mastery of vacuum pressure settings is critical for ensuring uniform material thickness and high-quality finished products. Proper control of vacuum pressure reduces material waste and enhances production efficiency in manufacturing processes.

Trimming/Cutting

Vacuum forming technicians specialize in trimming and cutting molded plastic sheets to achieve precise shapes and sizes as per product specifications. Utilizing hand tools and automated cutting machines, they ensure clean edges, maintaining material integrity and minimizing waste. Expertise in interpreting design patterns and quality control standards is essential for producing accurate and defect-free components.

kuljobs.com

kuljobs.com